For the private sector, a tractor is more than necessary. Bags with agricultural products, harvested hay, the same building materials - all this needs to be moved somehow. You can’t apply it manually, but a small iron “assistant” is just right.

There are two ways to get a mini tractor for your farmstead: either buy it if there is enough money and it’s not for you to care, or assemble an “iron horse” from improvised materials. We will not consider the purchase, as practical people, but we will get acquainted with one of the options for self-assembly of the tractor.

As a source material for the future vehicle, we will take the "people's" car LuAZ somewhere in the landfill. Or buy from a neighbor.

What do we need out of this whole pile of scrap metal? We leave:

- gearbox;

- bridges;

- electrician;

- wheel reducers;

- steering mechanism, and do not forget the steering wheel.

We sell the rest for scrap metal, getting a double benefit - we will earn money and get rid of trash.

Now you need to solve the problem with the engine. As an option, we buy Sadko DE-300 from a walk-behind tractor plus wheels (4 pieces 6x12).

The speed of our engine is “good”, but for a tractor it is somewhat overestimated. It's not a race car. Therefore, we reduce them by 3.5 times by installing the appropriate pulleys.

The transmission of torque from the engine to the gearbox can be organized using a profile B belt. It is better to install two at once.

The frame is the main supporting structure. It can be welded from a 40x40 profile. It will be quite acceptable, but rather weak, as for transporting heavy things. Therefore, it makes sense to immediately take a profile not 40x40, but 40x80. A margin of safety won't hurt.

After all of the above is assembled into one structure, we will see the fruits of our own heroic labor in front of us.

Hydraulics - consists of a hydraulic cylinder 75x100, a distributor P80, a pump NSh-10.

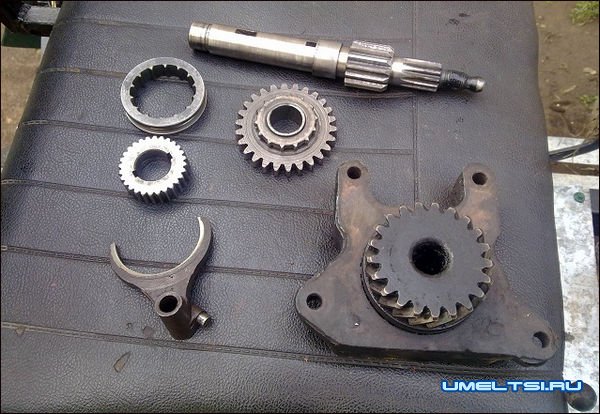

The operating mode of the pump is 1000-1100 rpm. The pump shaft is the outgoing shaft from the clutch flywheel. But due to the fact that the constant operation of the pump is not always required, it is advisable for it to make a switchable drive. To do this, we take a gearbox from a Ural motorcycle. We remove the necessary: a shaft, a splined coupling, a shift fork, two gears, a chain.

![]()

On the removed shaft, we will need to put on an asterisk, but before that, the shaft needs to be finalized. First, we cut the shaft, then we increase it by 5 centimeters so that the sprocket can be installed in its place.

We make the drive housing ourselves by welding it from a 40x40 corner. The drive is a unit that requires constant lubrication, which means that it must be filled with oil. It's clear? Then do not forget to make it airtight and install an oil seal on the shaft.

Everything is ready, now he can look at the included pump.

And off.

Assembled.

In conclusion, two words on hydraulics. The central section works with a hitch. Clutch brought forward with a rotary shaft, brought back with a hydraulic cylinder for a mower, dump truck, etc.

"Live" to see the work of hydraulics and our "brainchild" in a fully assembled state can be on the provided video.