For the manufacture of forged products, two methods are used - cold and hot working. The first method is characterized by low labor intensity, but requires the presence of a special tool. In most cases, you can make a cold forging machine with your own hands, guided by standard drawings.

Principles of cold forging of metals

For the production of metal forged products, it is necessary to ensure the process of their controlled deformation. In this case, the structure of the material, its technical and operational properties should be taken into account.

The principle of cold forging is based on the influence of external factors on the crystal lattice of the material. It consists of grains of irregular shape. As a result of the distortion of the structure, which is performed by the cold forging machine, there is a compaction and a change in the configuration of the workpiece. Since one of the conditions is the preservation of the properties of the part, it is necessary to select drawings for the production of machine tools.

Features of cold forging metal, requirements for fixtures for this:

- it is possible to process only low-carbon steels, which have a high degree of ductility;

- bars of various sections are used as blanks;

- preliminary calculation of the dimensions of the final products. In the process of their production, constant monitoring of geometric parameters is necessary;

- use of various machines to form the desired configuration.

Currently, a number of special tools are used for the artistic processing of metals by cold forging. Some of them you can do yourself. But for this it is necessary to first study the drawings and the specifics of production.

Forged products can perform several functions at the same time - aesthetic and operational. This applies to barrier structures of various configurations, for example, a wave.

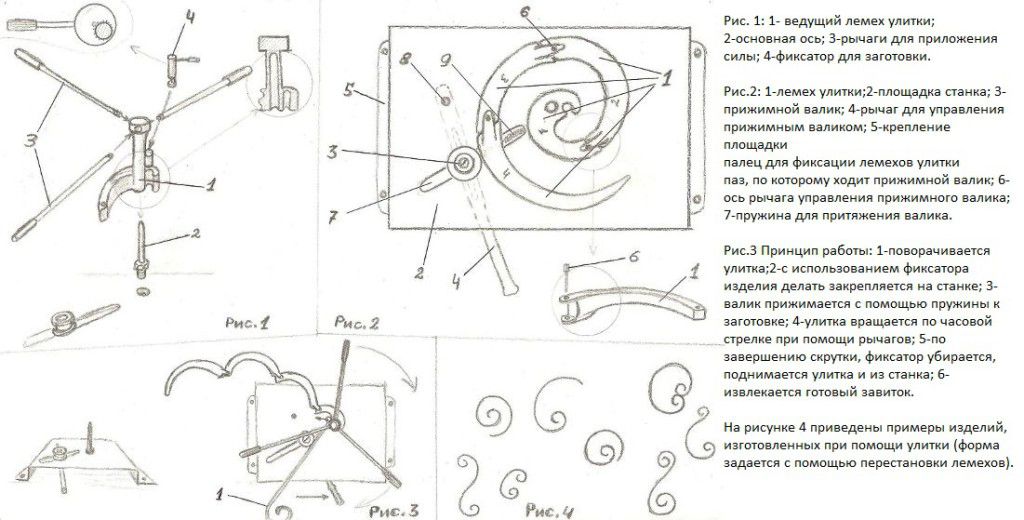

Snail for cold forging

The most common and in demand are home-made snail-type cold forging machines. With their help, spiral blanks are formed. The design of the equipment allows you to make it yourself.

The drawing of the "snail" machine can be adapted for the production of a specific type of artistic forging product. To do this, you need to know the following parameters:

- minimum and maximum radius of curvature of the workpiece;

- geometric parameters and shape of the source material;

- planned performance.

For mass production, it is necessary to make an electric forging machine. If you plan to work at home, manual models are suitable.

As a basis for the design of the volute, it is necessary to use a steel sheet with a thickness of at least 3 mm. This will allow you to bend large cross-section bars.

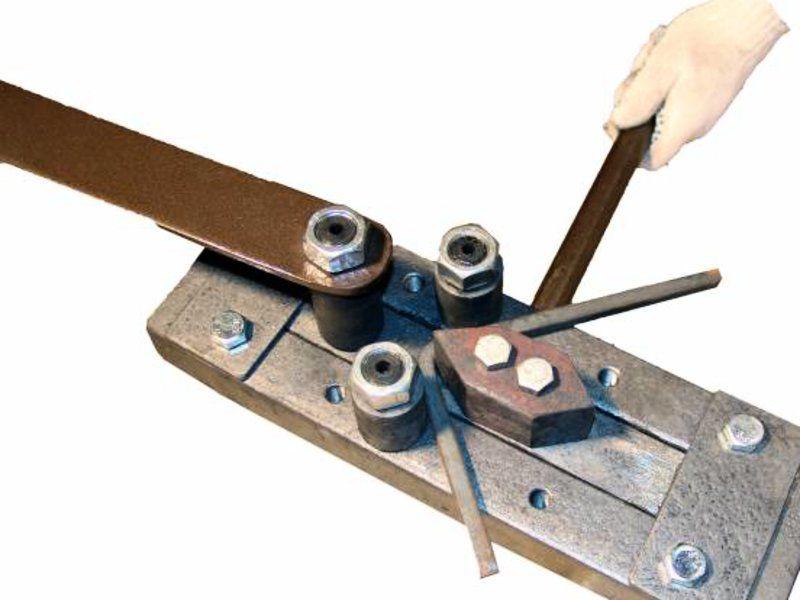

To form various angles, a manual bender is needed - one of the most required devices for cold forging metal. It consists of a steel plate on which there are two support shafts and a moving stop.

The workpiece is placed between the support shafts and the wedge. The latter has a displacement mechanism towards the stops. As a result of this action, bad things happen. steel bar processing. In this way, forged products of various shapes can be made.

Features of the use of a bender, necessary for the correct drawing up of its drawing:

- preliminary calculation of the deformation angle;

- an additional bending part can be provided in the design. To do this, install another rotating shaft;

- table mounting bracket.

It is necessary to use tool steel for the production of bending. This is due to the high loads during operation. Additionally, you can collect elements of the "wave" type on it, but for this you need to upgrade the original drawing.

Minimum and maximum bending radius for thin. forging must be calculated based on the geometric parameters of the workpiece.

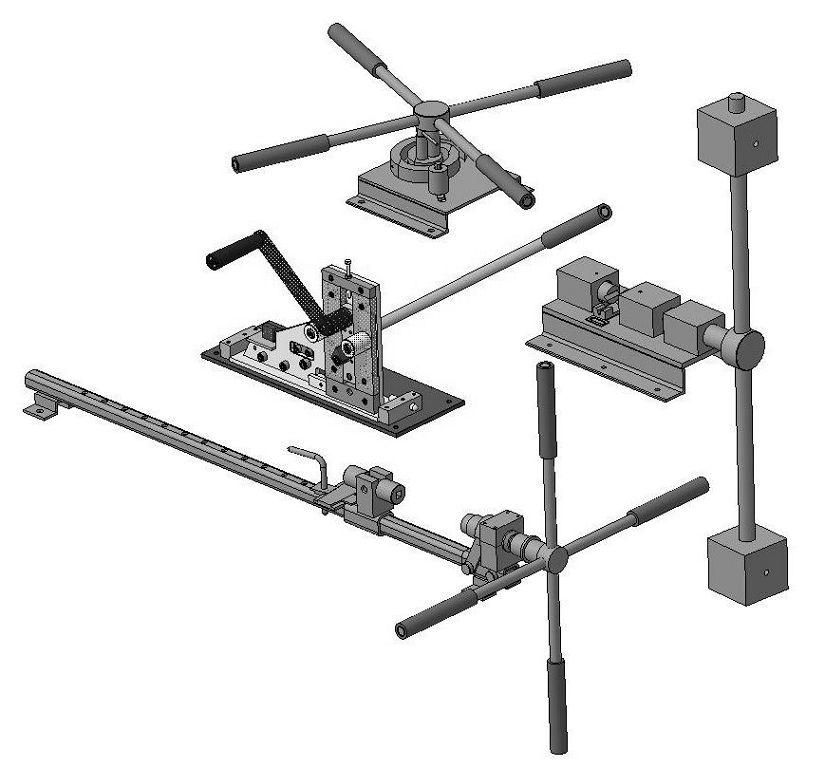

Twister for cold forging

It is difficult to imagine modern artistic forging without screw-shaped elements. For the production of such thin. parts are designed twister - a home-made machine for cold forging.

A feature of this tool is the unwinding of the twig along the axis. Structurally, the drawing of the machine consists of two parts - fixing and movable. The part is attached between them and its information is performed with the help of a rotary knob.

Performance features of the device:

- calculation of the pressure lever to minimize the efforts for the production of blanks;

- the ability to change the distance between the fixing elements of the tool. This will allow you to make parts of various lengths;

- it should be taken into account that the formation of the spiral occurs from the side of fixation.

Thanks to the twister, it is possible to make forged elements for window bars, steel barriers, etc.

This is the main list of cold forging machines. But besides them, various equipment is used, designed to create a truly thin. products.

The video shows examples of machines for cold forging metals at home: