Furnace heating is experiencing a rebirth. Long-burning stoves are considered the best in the rating of heating equipment. Their fundamental advantages are efficiency, economy, the ability to generate more heat and keep it longer. One of the main advantages of such a furnace is the ability to make it with your own hands. To do this, it is enough to have the initial skills of a locksmith and a welder.

What is the benefit of autonomous heat generators of long burning

Why autonomous stoves are more profitable than central heating? The fact is that powerful industrial heating boilers with 100% efficiency lose up to 30% of heat when passing through main and distribution pipelines. Autonomous heating works without heat loss, and its performance is determined by the efficiency of the boiler used for heating. Homemade stoves can be unsightly in appearance, but have an efficiency of more than 90%. You can heat them with wood, coal and waste.

Efficient and economical wood fired pyrolysis boiler retains heat for a long time

What is pyrolysis and sublimation

High efficiency and illegibility in the fuel is achieved through pyrolysis - the thermochemical decomposition of solids. In this case, easily combustible components are formed. Pyrolysis processes can take place in a divided space, and this design is called pyrolysis. If the process takes place in a slowly smoldering layer, then this is a long-burning smoldering stove. The separation of volatile components is called sublimation.

How does pyrolysis work?

The pyrolysis process goes through four stages:

- Drying - excess moisture is removed from the firewood. It is carried out in the process of preparation or in the furnace due to its heat.

- Pyrolysis - sublimation of volatile components, decomposition of heavy components - resins and bitumen to volatile. The fuel mass begins to carbonize, that is, to char.

- Combustion of pyrolysis gases when reaching the flash point under the influence of high temperature and free oxygen. Carbon burning begins when the temperature rises above 600 degrees.

- After the combustion of volatile components and the main mass of carbon, reduction reactions begin - the release of carbon monoxide, free hydrogen and oxygen.

In order for the efficiency to be high, when designing the equipment, it is necessary to ensure that the reducing gases are retained in the hot zone and that heated fresh air is also provided there. With rapid cooling, the energy spent on recovery will fly out into the pipe. Don't forget that carbon monoxide is poisonous.

Note: one of the main advantages of a slow burning stove is ease of operation. Firewood is loaded into it once or twice a day, and ashes are raked out once or twice a week.

Solid fuel stove potbelly stove

Outside the cities, firewood is the most affordable, so the most popular long-burning stove is wood-burning. They heat it not only with firewood from the ridge, but also with waste wood - shavings, sawdust, fiberboard and chipboard waste, small brushwood, straw, etc. There are many heating systems on wood and wood waste. Consider the most efficient, the efficiency of which is more than 70%.

The simplest potbelly stove can be made by hand

A potbelly stove is an economical stove that appeared in Russia after the revolution, during the time of war communism, when many had to endure hardships. The genius of the potbelly stove is that it instantly warms up, as well as the simplicity of its device, the prototype of which was the Russian stove. The upper door is for laying firewood, the lower one is for regulating combustion by supplying air through the ajar door.

The task of the potbelly stove is to keep the heat in at least one room at minimal cost. When using coal, the grate is removed, and the air from the blower is directed to the furnace. It is important not to stuff it chock-full - the volume of the bookmark should be no more than a quarter of its volume. The afterburner is a long horizontal or slightly inclined part of the chimney. Made of metal, it keeps the heat in the room.

Important! The potbelly stove can work on all types of solid fuels, except for sawdust. It is made in the form of a box from sheet steel or round from a barrel. Chimney diameter - 85 - 150 mm.

Such a potbelly stove will not only warm, but also decorate the interior.

When fired, any potbelly stove is red-hot, so its upper surface can be used as a hob. A screen should be installed on the sides at a distance of 40-60 mm from the oven. It protects the room from infrared rays and maintains the temperature at an optimal level.

On the basis of a potbelly stove, you can make a home-made boiler for long burning on wood. To do this, instead of the screen, a U-shaped metal water heater is installed. The distance between the furnace body and the boiler must be the same as the screen offset.

Heating boilers based on a potbelly stove

To heat a multi-room house, you will need a flow-through water heating circuit with a long-burning solid fuel boiler. Such a system can be set up in two ways. The principle laid down in the potbelly stove is taken as a basis.

The first method or boiler number 1

Features of once-through and heat storage pyrolysis boilers:

- The temperature in the combustion chamber is a parameter necessary to control the process.

- Heat dissipation optimization is directly proportional to the boost intensity.

- The insensitivity of the system to the temperature of the walls of the combustion chamber, so the water heater can be built in a technically convenient way.

- Additional loading is possible at any stage and in any allowable quantity.

Note: The type of fuel affects the rate of pyrolysis and the composition of gases. These factors are taken into account by regulating the back pressure at the outlet by throttling the chimney. Regulators of industrial solid fuel boilers are supplied with marks indicating the recommended type of fuel.

The efficiency of once-through boilers can be over 90%. They require power to operate. When shutting down, to further start the system, it is necessary to rake out the caked mass and make a new bookmark in the furnace.

Solid fuel steam boilers use different types of fuel

The second method or boiler number 2

A pyrolysis boiler with a water heater, which does not require electricity and automation, works on the principle of counteraction of two square-cube laws. This refers to the laying of fuel and the lining of fireclay bricks.

The algorithm of the brick oven:

- At the beginning, the intensity of the pyrolysis process is provided by the sublimation of the lightest volatiles. The "first heat" goes through the smoke circuits, being absorbed by the lining.

- At the stationary stage, the lining serves as a thermal buffer: in case of excess pyrolysis heat, it absorbs it, and releases it when it cools down.

- Upon completion of fuel carbonization, gradual heat transfer by the lining occurs, preventing the temperature from dropping below the critical point.

Loading firewood or coal into a boiler with a thermal buffer is carried out gradually. Sharp fluctuations in temperature are contraindicated for her. If too sluggish fuel is used, it may stall. If there is too much fuel, there is a risk of an accident. If the first heat is not suppressed, the efficiency will not exceed 76-78%, since the instantaneous heat transfer by the lining to the outside is excluded.

English fireplace

There are legends about the attractiveness of fire, its decorative and aesthetic function is of great importance for a person. Can an ordinary person build a long burning stove in his house in order to enjoy not only the warmth, but also the beauty of the fire? The main thing in such devices is not heat transfer and efficiency, but the ability to contemplate the fire during the day.

A handmade English-style fireplace will decorate your interior

There are such designs, and the British came up with them. The classic English fireplace has a smoke tooth, reminiscent of a threshold in a Russian stove, which forms the circulation of flue gases, which does not let fresh air up, directing it to the bookmark, as happens in a potbelly stove.

Due to the large mouth, the efficiency of the fireplace is small - no more than 50%, even if there are smoke turns in the chimney. Smoldering and heat generation from evening to morning occurs only when using Cornish coal or similar coking coal. It is said that in the old days English lords stoked the fireplaces with the rhizomes of pines growing on the coastal rocks.

An example of another "long" fireplace is an ordinary Dutch woman. The blower closes before kindling, firewood is loaded onto a quarter of the firebox, its door remains wide open. The main part of the heat flies into the pipe, but the decorative effect is guaranteed.

The simplest do-it-yourself oven

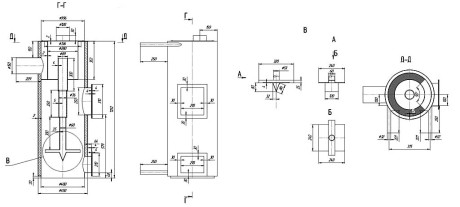

Solid fuel boilers for long burning, which were mentioned above, are difficult to do with your own hands according to the scheme. The drawings below will help the home-made master to build the simplest heating device on his own. Equipment power - 35 kW, efficiency - up to 85%, burning time - 12 hours. Coal or fuel pellets are used as fuel. Loading with firewood reduces the efficiency to 75%, the burning time is reduced to 8-10 hours.

A drawing of the design of the furnace will help you make it yourself

Slobozhanka - an effective inexpensive furnace design

Slobozhanka is a product of folk art created in the Slobozhanshchina. In terms of its effectiveness, it is better than the products invented by the Soviet branch research institutes.

Scheme and the possibility of improving the design

Slobozhanka is a full-fledged miracle wood-burning stove with a hob. Air is supplied to the smoldering bookmark from the side along a U-shaped trajectory: down the L-shaped air duct and then through the perforated casing. Access is provided to all layers, which contributes to more active pyrolysis, so Slobozhanka works well on coal and pellets. This is an economical device with an efficiency of more than 80%.

The power of the equipment can be increased by complicating its design: stretching the inner perforated casing to the full circumference. To equip the blower with a throttle, a third narrow casing is made to cover the air intakes from the outside.

Vertical Slobozhanka is made on the basis of a barrel

Slobozhanka with mushroom hat

The traditional Slobozhanka has disadvantages:

- It does not accept greasy and tarry fuels. Household waste, chipboard and fiberboard waste form hard deposits on the edges of the openings of the inner casing and the perforated casing of the air duct.

- Careful refueling of the unsmoldered bookmark is required, since at least a small smoldering area should remain free near the perforation of the casing. If this is not foreseen, after the bookmark burns out, the stove will cool down.

The design with a central conical perforated air duct with a mushroom cap is the development of one of the Soviet mailboxes. Created on the basis of Slobozhanka. The cone was freely installed in the unloading hatch of the firebox and removed for cleaning.

The edges of the cap threw the fuel to the edges, a smoldering ring formed under it, which was necessary for stoking the stove. Additional loading could be carried out in any quantity and at any time. Due to the edges of the hat, the air was directed to the smoldering zone, which ensured the omnivorous nature of the structure.

The disadvantage of the "slobozhanka with a fungus" was that when burning household waste or damp pine, it was necessary to check the soot. The cone could stick tightly. It was difficult to remove it without distorting it in this case.

Video: Slobozhanka top burning stove

Slow-burning household stoves are a promising direction in heat engineering. Combining with alternative energy resources and waste-free industrial technologies will help prevent an environmental catastrophe. With the external simplicity of the design, the processes in them are complex and not fully developed. These ovens have great potential. Their development and creation is a fertile niche for the creativity of talented DIYers.