To complete the majority of small school or home workshops, a STD-120M woodworking lathe was used. Unlike its more powerful counterparts, it has optimal technical and operational characteristics for processing wooden blanks. But not only this it differs from similar models.

The STD-120 M woodworking lathe was developed on the basis of the previous model of the series - 120. It differs from its predecessor in additional protective components in the device - covers, guards, etc. Also, the electrical circuit has undergone modernization, the noise level during operation on the equipment has been significantly reduced.

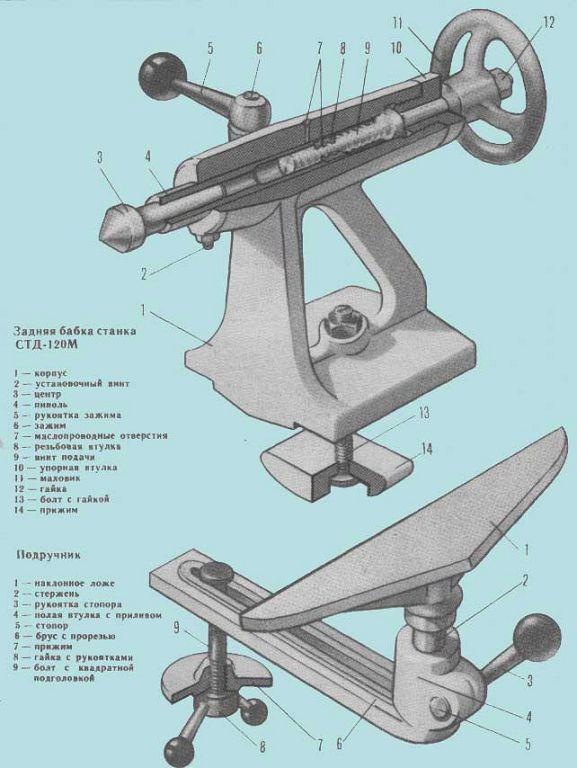

To analyze the characteristics of the equipment, it is worth familiarizing yourself with the specifics of its design in more detail. Like the 120 series model, it consists of a bed with guides, which is mounted on support elements. For greater stability, they are attached to a wooden base.

The drive STD-120M is carried out due to the movement of the electric motor. It is located on the left side of the diagram. The transmission of torque occurs using a belt drive. To do this, there are two pulleys, one of which is mounted on the motor shaft, and the second - on the headstock spindle.

The device of the machine has the following characteristic features:

- the rotation speed is changed by transferring the belt to a certain shaft stream;

- the button block is located on the headstock. This is due to optimal access to the on / off mechanism during operation;

- replaceable spindle nozzles are included in the standard equipment;

- the turning zone has additional protective shutters with transparent windows;

- an additional unit can be connected to remove chips and dust.

To increase the accuracy of the operations performed, the STD-120m machine has a local lighting circuit. For its operation, a step-down transformer is provided.

In order to increase the safety of operation, the design has an electric interlock for the protective structure of the belt drive. For this, switch B2 is provided.

Equipment technical parameters

Before starting work on the STD-120 machine, you should familiarize yourself with its technical and operational characteristics. To connect the equipment, you will need a 380 V power line. The power of the power plant is 0.4 kW.

The brand of the installed electric motor is AOL 21-2. In the event of a breakdown, it can be replaced with a similar one. It is important that, in addition to power and speed (2800 rpm), the shaft diameter for installing transmission streams matches.

It is also necessary to familiarize yourself with the device and the characteristics of the drive transmission:

- type - V-belt;

- brand drive belt This designation is taken from GOST 1284-68;

- two streams in the design of the pulleys;

- the maximum number of speeds is 2;

- the nominal speed of the spindle can be from 1100 to 2150 rpm;

On the STD-120 machine, wooden blanks with a length of up to 450 mm can be processed. In this case, the diameter should not exceed 190 mm.

An important point is the overall dimensions of the turning equipment. They are 125 * 57.5 * 55 cm with a mass of 100 kg. For normal operation, the machine must be installed on a platform base. It is intended not only to equalize the level, but will also dampen the fluctuations that will inevitably appear during operation.

When choosing a workpiece, you should take into account the distance between the centers, which is 50 cm. Their height is 12 cm.

Since the STD-12M machine does not belong to the category of professional machines, special requirements for maintenance and operation are imposed on it. Its main purpose is to introduce students to the basics of turning. Therefore, safety requirements are increased.

To increase the stability of the equipment, the base is best made of steel structures or concrete. Its height should be from 600 to 800 mm. The floor in the workplace should not be slippery. Its device should not include elements that interfere with the performance of operations.

In addition, the following features of operation should be taken into account:

- wood blank should not contain knots and cracks. Its humidity cannot exceed 20%;

- large parts should be processed at minimum speed;

- moving parts must be lubricated at least once a year or after 500 hours of operation. At the same time, its device is checked for damage and defects.

Designed for small do-it-yourself repairs. Often this refers to the restoration of the working capacity of the tailstock and headstock. Before performing these works, you should familiarize yourself with the device of the machine, as well as study the instructions for its operation.

The video material describes in detail the methods of turning on turning equipment STD-120: