A mini tractor for a small farm is, if not necessary, then a very useful technique. The unit mechanizes plowing, harrowing, cultivating the land, removes and takes the crop from the field, and helps in forage harvesting. The capabilities of the device are expanded by additional equipment.

There are enough proposals for mini-equipment on the agricultural machinery market, but the prices of the simplest and least functional Chinese-made machine start at 120 thousand rubles. A home craftsman can significantly reduce costs by making a mini-unit, equipment for it with his own hands.

Choosing the parameters of the future car

Consider on what factors and parameters the stability of the minitractor depends.

Power point

The master needs to clearly decide what you want to do with a home-made unit and in what area. The power of the power plant will largely depend on this. The experience accumulated by specialists allows us to recommend:

- engine installation 4-7 hp with the area of the cultivated area up to 20 acres;

- 9-17 HP up to 50 acres;

- 20-40 HP up to 4 ha.

For the operation of additional equipment, the engine must be equipped with a power take-off shaft.

Chassis, steering and transmission

Most home-made units have a frame structure on two axles with pneumatic wheels. The drive can be on one or both axles. It is advisable to use a mechanical type transmission with a gearbox, clutch assembly, cardan shafts and axles from a light car or agricultural machinery.

In the same way, steering components, brake systems, and electrical equipment are selected.

Having sufficient capacity of the hydraulic pump, hydraulic motors, distribution devices and power hydraulic cylinders, it is realistic to equip the unit with a full volumetric hydraulic drive, which will make it possible to abandon mechanical transmissions and simplify the steering scheme.

Such a solution will greatly facilitate the creation of a machine with a breaking frame - two half-frames are connected by a power hinge assembly, which increases the maneuverability and maneuverability of the minitractor, provides copying of ground irregularities by the axle wheels.

The use of a caterpillar-type mover significantly complicates the design, it will require the presence of light links of the caterpillar belt, the development of power moment transmission units for each of the belts with different parameters (for turning and turning), and the installation of track belt tensioning mechanisms.

Examples of developments by homemade masters

Let's turn to the well-known home-made mini tractors, which received worthy reviews in the world of agricultural machinery of their own manufacture.

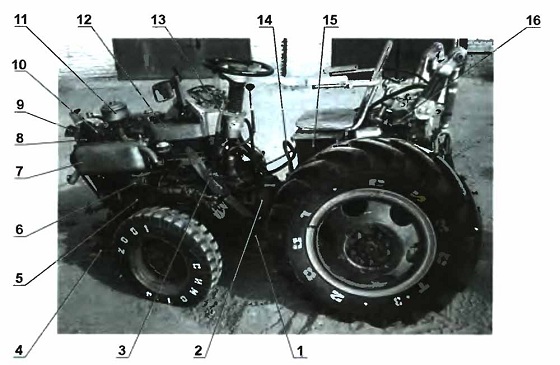

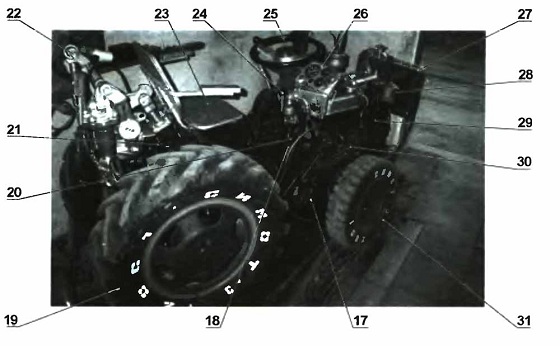

Minitractor "Volchok" with a breaking frame

- 1 - the articulated frame mechanism of the articulated type (cardan cross of the MAZ vehicle);

- 2 - drum-type braking mechanism (GAZ-51);

- 3 - pedal drive of the clutch mechanism;

- 4 - front axle wheel suspension unit (ZAZ-968);

- 5 - two-cylinder diesel 20 l. With.;

- 6 - starter starter (GAZ-51);

- 7- exhaust damping unit (ZAZ-968);

- 8 - electric generator (GAZ-53);

- 9 - fan of the cooling system;

- 10 - pump of the cooling system;

- 11 - air filter housing;

- 12 – tank for fuel;

- 13 - hand brake drive;

- 14 - cross of the hydraulic system;

- 15 - battery box;

- 16 – hydraulic system tank and pump NSh-10;

- 17 - power take-off;

- 18 - checkpoint (GAZ-51);

- 19 - wheel (Belarus);

- 20 - hoses of the hydraulic system;

- 21 - hydraulic distributor;

- 22 - hitch assembly (Belarus);

- 23 - operator's place;

- 24 - gearshift lever;

- 25 - power steering (electric car);

- 26 - instrument panel (Belarus);

- 27 - radiator of the cooling system (Lada);

- 28 - oil filter;

- 29 - fuel supply pump;

- 30 - gas pedal;

- 31 - wheel (electric car).

a - turn left; b - turn right.

1 - steering wheel with a control unit for the hydraulic turning cylinder; 2 - half-frame rack; 3 - attachment point of the hydraulic cylinder rod; 4 - steering cylinder; 5 - rear semi-frame; 6 - power hinge of the breaking frame; 7 - flexible hydraulic hoses

Making a clutch for a mini tractor

The clutch basket casing is connected to the motor through an adapter with coaxial mounting holes. The device itself was used from GAZ-51, the mechanism is turned off by a hydraulic drive.

Mini tractor features:

- components and parts are used from used cars and agricultural machinery;

- a breaking-type frame is assembled from two half-frames and a crosspiece from a MAZ truck. Provides high cross-country ability and maneuverability of the machine, copying the terrain with pneumatic wheels, directional control;

- a cardan shaft with a pair of end crosses, transmits the power moment from the box to the bridge, regardless of the "kink" of the frame;

- a drum-type service brake is mounted on the box shaft;

- the drive axle is used from an electric car, rigidly fixed to the semi-frame;

- front axle suspension independent. Shock absorbers, springs, levers are used from ZAZ;

- the machine can be converted into tracked and all-wheel drive versions.

The Volchok unit is converted into an all-wheel drive mini tractor with its own hands in the following order:

- Behind the gearbox, a transfer case from the GAZ-69 is installed through the intermediate cardan shaft, which transmits the power moment to the drive axles, the presence of a reduction gear in the device allows, if necessary, to increase the traction force.

- A bridge is mounted on the front half-frame - an analogue of the rear axle of a minitractor.

- The main gear of the front axle is connected to the transfer case through a cardan drive.

Alteration of the "Volchka" into a caterpillar minitractor with your own hands:

- Build a caterpillar type propeller. For this purpose, a large diameter tire with cut sides is used. We use solid rubber wheels from transport carts as rollers.

- We fix the semi-frames rigidly relative to each other (the power hinge does not work).

- We dismantle the front suspension, on the front half-frame we fasten the roller units with the track tension mechanism.

- We dismantle the rear axle, in its place we install a shortened axle from the GAZ-21 with the main gear and differential, we connect the hydraulic control of the drum brakes separately for each side. We install rollers in place of the rims.

- Two drum brake pedals on the rear axle, through the operation of the differential, provide a change in direction.

- We dress and pull the caterpillar tape.

Optional equipment

Having made a trailer with your own hands, you will significantly expand the functionality of a mini tractor, minimizing financial costs.

We start manufacturing with a supporting frame - welding of round or rectangular pipes (at least 40 mm in cross section) of the product frame. The axle of the wheelset is made of a steel rod with a diameter of 35 mm. The axle is connected to the carrier frame by a longitudinal hinge, side spars and corner supports.

The body box is made of edged planed boards connected with screws and metal corners.

To attach the product to the minitractor, an articulated drawbar is used, inserted into the tubular body. The coupling with the vehicle is fixed by a chain-type fuse.

TELL YOUR FRIENDS

In contact with