Any of the owners of a garden plot knows how tedious and painstaking work can be associated with the cultivation of various crops. Moreover, such work is most often done by elderly people, who are not so easy to master the loads associated with tillage before planting and during the cultivation of garden plants. To simplify this difficult process, there is an electric cultivator, which can be done with your own hands at home. Below are the simplest models of such structures.

Cultivator: concept, scope

Electric is a device equipped with an electric drive and designed for cultivating the land. Thus, it can be a full-fledged analogue of manual labor and will perfectly cope with the task of loosening the soil, fertilizing, creating beds and weeding them. In simple terms, an electric cultivator is a mechanized chopper.

Attention! The device in question is absolutely not intended for cultivating large agricultural areas. But it is perfect for caring for a small flower garden, garden plot, etc.

The main task of the cultivator is to give the soil the necessary structure (it removes a layer of earth no more than 30 cm deep), thus preparing it for fertilization, watering and other manipulations with the area planted with crops.

Among the main advantages of an electric cultivator are the following:

Creating an electric cultivator with your own hands

With the help of simple devices, which can be found in almost every house where a man lives, you can make a simple, easy-to-use and, most importantly, practical cultivator powered by the mains. The following are the simplest models of such products.

Starter design

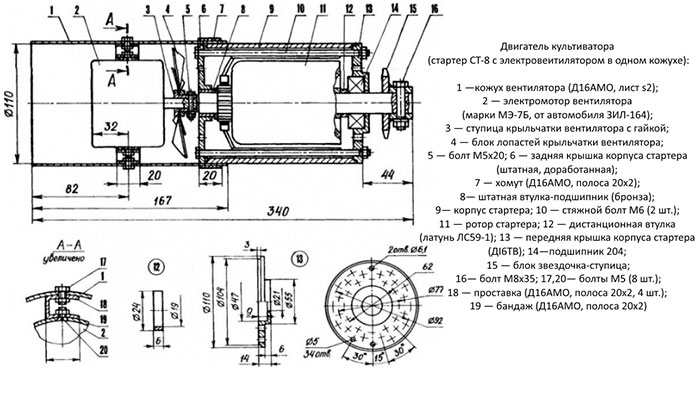

A cultivator from a starter can be made if there is a starter from some car in the home garage. In our case, we will talk about the starter from Gas-51. In order for the part to perform its functions effectively and over a long period of time, it will be necessary to perform some manipulations with the starter to improve it.

It is necessary to shorten the starter shaft a little, after which it will be necessary to replace its front cover and make many holes with a diameter of about 5 mm in both the front and rear cover. Through these holes, the air will be blown with high quality by a fan that can perform this function using an electric motor shaft, for example, from some old truck. At the ends of the working shaft, cultivator cutters should be installed.

Engine

The semi-finished unit is mounted on a pre-prepared power platform made of sheet steel.

Advice. Since the design will turn out to be quite cumbersome, care should be taken to strengthen the base for the cultivator. For this purpose, longitudinal stiffeners are used, which are welded to the power platform.

Bulgarian construction

From the grinder, you can make a compact cultivator of low power. It is quite enough for weeding between rows in the garden or in the garden plot. Bulgarian in this design acts as an electric drive.

All other components for creating a cultivator can be taken from an old motor cultivator. The average power of the grinder is 600 rpm. Therefore, a cutting wheel is not suitable for it. The best option is to use a pulley with a groove for the V-belt.

An angle grinder suspension unit is welded to the frame of the old cultivator. To connect the finished product to the mains, you can use an extension cord on a reel.

The finished product will turn out to be quite light, compact, and high-performance (the cutters of the device will produce about 300 rpm).

Advice. To make it more convenient to work with an electric cultivator and your hands do not feel overstrain, small pieces of a rubber hose can be put on the handles of the product, matching the diameter of the pipes of the cultivator.

Washing machine design

If an old, completely useless (but working) washing machine is lying around in your house, do not rush to throw it away: try to make a wonderful small electric cultivator using its engine.

To create it, you need a simple set of parts:

- An ordinary wheel with a diameter of about 1.5 m, which will perform the simplest function - a motor one.

- An electric motor from an old washing machine (even the Soviet version will do).

- Metal corner about 3 m long.

- Twin wire.

- Drum and a piece of tin to create a protective casing.

- Springs from the car (they will make excellent knives).

- Reducer, toggle switch and start button.

Now you can proceed directly to the assembly of structural parts. The first step is to complete all welding work. Then comes the preparation of knives for the cultivator. To make them really work, you need to follow a simple rule: each of the knives must have its own trajectory of movement, and it should not intersect with all the others.

The engine will need two windings: working and starting. The first one will be connected to the network in a constant mode, while the second one is needed only to start the finished garden power tool.

That's all the subtleties that you should know to create a simple and efficient cultivator design that works on the site. Good luck!