Holidays outside the city, whether it is a summer cottage or a picturesque glade in the forest or near a pond, very often involves cooking barbecue. Of course, for this you can get by with a few bricks and a couple of metal crossbars, but the real pleasure of cooking meat on skewers can only be obtained next to a convenient and practical barbecue. A solid construction can be made from thick sheet metal. If there is no such thing on the farm, then you should not rush to the construction market. An excellent device for cooking meat can be built with your own hands from an ordinary gas cylinder.

Features of a brazier made on the basis of a tank for liquefied gas

A gas cylinder is an excellent basis for many homemade designs. Good solid metal, a practically finished form and several standard sizes make it possible to obtain a potbelly stove, an indirect heating boiler, an autoclave and other equipment necessary for the household with minimal labor. The thick walls of the liquefied gas container can withstand high temperatures, so it is the best suited for making a smokehouse, barbecue or barbecue. Other advantages of the design are also known:

A brazier built from a tank for household gas has practically no drawbacks. Some consider large dimensions to be a minus, but what prevents them from taking a smaller cylinder, for example, 27 liters? The negative aspects include perhaps the semicircular shape of the bottom, which is not very convenient during the ignition of firewood. On the other hand, with this configuration, the coals will be closer to the edges of the skewers. Due to this, the outer pieces of meat will be better baked, which, when cooked on a traditional rectangular roaster, often remain raw. Experts believe that the spherical walls of the brazier are not entirely suitable for cooking barbecue, as they interfere with processes that help the rich aroma of baked meat “open up”. In the future, we will touch on this issue, revealing the secret of how to avoid the disadvantages associated with the round shape of the bottom.

Preparatory activities

Before picking up a welding machine, you need to pick up a gas cylinder and prepare it for work, draw up a rough sketch of the future barbecue and stock up on the necessary tools and materials.

Which bottle can be used

For the manufacture of brazier, any gas cylinders of a cylindrical shape are suitable. The best option is a fairly roomy and most common 50-liter container for household propane-butane. If you want to get a more mobile and lightweight design that can be transported in the trunk of a car, you can take a standard 27-liter cylinder. It should be borne in mind that the width of the working space of a portable barbecue may not be enough due to the spherical shape of the sidewalls.

Gas cylinders are made of high-alloy low-carbon steels 30XMA, 45, 34CrMo4, 30XGSA. The high content of ligatures and the reduction in the amount of ligatures in the metal makes the alloy more durable and improves anti-corrosion properties.

An ideal option for a stationary barbecue would be a car gas cylinder of 50–80 liters. It has an increased diameter, so it will be much more convenient to kindle firewood. In addition, such a vessel has a high capacity. Its width makes it possible to use the entire length of a standard skewer, and this will allow you to cook dinner for a large company. The only caveat is that finding an unnecessary car gas tank will not be easy, and buying a new one will not be financially feasible.

Gas cylinders are made of high-quality alloy steel with a thickness of 3 or more millimeters, so even if the container has been standing in the open for a long time, it is likely to be usable. If the vessel is very rusty, then you should not waste time on it - it will not be difficult to find a workpiece in good condition.

How to protect yourself from an explosion

Even if the valve of the used container is completely unscrewed and the gas does not come out of it, do not rush to take on the grinder. Despite the fact that inside the cylinder the pressure was equal to atmospheric pressure, most likely, unsafe substances remained in it - propane-butane and condensate. The latter is drained by turning the vessel upside down, and in order to completely remove the explosive contents, the cylinder is filled to the top with water and left for several hours. Only after this requirement is met and the liquid is drained, you can start cutting and welding metal.

Schemes and drawings

The brazier from a gas cylinder is such a simple structure that it does not require careful design. Nevertheless, at the preparatory stage, it is recommended to draw up a small drawing or sketch of the future structure, indicating the dimensions of all its elements. This will make it possible to determine how much and what kind of rolled metal will be required, and will also allow you to properly plan individual processes. Perhaps the drawings and diagrams presented in our gallery will help you in working on the barbecue.

Gallery of drawings and diagrams

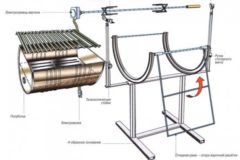

Scheme of a brazier with a supporting structure

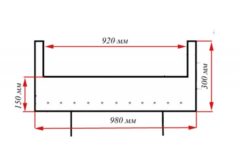

Scheme of a brazier with a supporting structure  Drawing of a brazier from a 50-liter gas cylinder

Drawing of a brazier from a 50-liter gas cylinder  The design of the brazier from a gas cylinder

The design of the brazier from a gas cylinder  Scheme of the movement of heated air

Scheme of the movement of heated air

Materials and tools necessary for work

In addition to the gas cylinder itself, you will need:

- pieces of steel pipes and corners;

- metal handles for the lid of the barbecue;

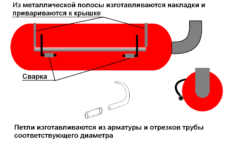

- door or furniture hinges;

- pipe with a diameter of 100 mm with a 90-degree elbow, if you plan to install a chimney;

- grill, which will be needed for barbecue;

- bolts with nuts or rivets.

In addition, you should prepare decorative elements designed to ennoble the structure, as well as a primer, paint and solvent that will be needed to paint it.

If we talk about tools, then we are sure that everyone who is interested in the issue of building a home-made barbecue will find them:

- welding transformer or inverter;

- angle grinder - angle grinder (colloquially "Bulgarian");

- electrodes Ø3–4 mm;

- cutting and cleaning disc for angle grinder;

- electric drill;

- a set of drills for metal work;

- clamps for fixing metal parts;

- long metal ruler;

- scriber;

- core;

- adjustable and gas key;

- set of wrenches.

If, after manufacturing, the brazier will be painted, then additionally prepare a brush attachment for a drill or grinder, as well as brushes or a spray gun with a compressor.

Making a brazier with your own hands from a household gas cylinder of 50 liters

Installation work is best done in a well-ventilated area or outdoors. The place where the assembly will be performed must be fairly even, otherwise it will not be possible to ensure the correct geometry of the structure and the brazier will be unstable.

When carrying out locksmith work, it is important not to forget about the safety rules, be sure to use protective equipment and overalls.

Step-by-step instruction

- Unscrew the valve. To do this, use a gas or adjustable wrench. Sometimes the shut-off valves turn sour so much that there is no way to unscrew it. In this case, the tap can be cut off with an angle grinder. Using the same tool, they cut off the lower support rim - with it the design will look unaesthetic.

- Mark the cutting points. The diameter of the 50-liter propane-butane tank is 960 mm, which allows it to be accurately divided into four parts. It is convenient to take a longitudinal seam as a reference point. Having laid the cylinder on a flat surface, a quarter of the diameter - 240 mm is measured from the welding line in both directions and horizontal markings are applied, which will divide the cylinder in half. An indent of at least 30 mm is made from the attachment line of the upper and lower parts of the vessel, after which circular lines are drawn. The distance between them is divided into equal intervals of 80-100 mm, on which the skewers will be laid. After that, mark the lid of the barbecue. Its length should be less than half the diameter, so 100 mm are measured from one of the longitudinal lines towards the horizontal weld. A parallel drawn strip will indicate the place of the cut.

- Having installed a cutting disc on the "grinder", they cut a line that divides the diameter of the cylinder in two. After that, the slot is marked into equal parts and the loops are welded. Their number can be from two to four (depending on size). After that, the cover is cut out along the circular marks, as well as the longitudinal line, which is located at a distance of 140 mm from the horizontal seam.

Do not rush to cut the entire cover at once. Subsequently, this will entail a lot of inconvenience associated with its correct orientation, setting gaps, etc. It will be problematic to do this without an assistant. If the loops are immediately welded along the line of the first cut, then in the future it will be possible to save a lot of time and nerves.

- In order for the upper door to be held in the desired position and not to break the hinges when tilted, limiters must be welded along the cut line. You can make them from 20–30 mm pieces of a steel corner with a shelf width of 40–50 mm. Fixing stops are mounted on both sides - this will avoid distortion of the cover.

The distance at which the door will recline can be changed by unbending the latches to the required angle. At the same time, a position is chosen in which it will be possible to easily reach the handles of the lid, without leaning forward much, and at the same time will not allow the structure to spontaneously slam shut.

- In order to prevent the door from falling inward when closing, a limiter must be welded around the perimeter of the circular cutouts. To do this, a strip 30–40 mm wide is cut out of sheet steel with a thickness of 1–3 mm. It is attached from the inside of the balloon with an interrupted seam.

Instead of limiters, you can use a piece of chain of the desired length, welding it with one end to the barbecue, and the other to the lid.

- Below the loops, a series of drillings Ø12–14 mm are made for skewers. Previously, these places were marked along the dividing line of the diameter. Slots or triangular cutouts are made on the front wall opposite each hole, on which skewers will be placed.

- Mount handles for opening the lid. For this, factory products with overlays made of wood or refractory composites are best suited - they will not allow you to get burned. In extreme cases, the handle can be made by bending a piece of metal bar or reinforcement in the form of the letter “P”.

- At the next stage, holes are cut in the bottom of the brazier for air to enter the combustion zone. To do this, the structure is turned over with the lid down, measured from the longitudinal seam 100-120 mm in each direction and horizontal lines are drawn. Setting aside 100 mm from these marks, strips are obtained, in which cuts are made every 50 mm. Drilling can be done instead of slots. In this case, holes with a diameter of 10–12 mm are made in a checkerboard pattern.

Cutting through the bottom for air supply is impractical for a number of reasons. Firstly, this will weaken the weld, which makes the structure more rigid, and secondly, the holes will quickly become clogged with fatty deposits mixed with ash and ash, and will cease to fulfill their functions.

- The hole for the valve must be welded. If the brazier is also planned to be used as a smokehouse, then the opening is expanded to the diameter of the chimney. After that, a chimney is welded to the cylinder.

On this, the main part of the work is considered completed. It remains to install the brazier on the legs and ennoble with an interesting decor, or simply paint the structure with heat-resistant paint.

Installation of supports for barbecue

There are several options for installing the brazier on legs, which is facilitated by the rather thick metal of its body. The first and easiest method is to weld four pieces of steel pipe or angle directly to the hull. Of course, the connection points must be carefully verified, and in the process of work, use a square and a building level, otherwise the design will look crooked and untidy. Everyone makes the height of the brazier for themselves, but there is also a standard recommendation - the distance from the ground to the plane of laying the skewers should be no more than 1 m.

It is worth noting that the method described above cannot add presentability and convenience. If you want to get a stylish, practical structure, then for this you need to make a frame-type support. To do this, a pair of side racks is made from a profile metal pipe 20x20x2 mm. In its upper part, a semicircular bed is welded from a metal tire, curved in the shape of a cylinder. Between themselves, both parts of the structure are fixed with the same metal profile so that a kind of underframe is obtained. The balloon is placed on the prepared bed and tacked by welding. In order to make the brazier more mobile, metal wheels can be attached to the legs.

A brazier made from a household gas cylinder can be taken with you when outing into nature. In order for it not to take up much space in the trunk of a car, the supporting structure is made collapsible. All that is needed for this is a 40-centimeter piece of pipe with an internal diameter of 18-30 mm and a 3-meter pipe with a diameter of 16-28 mm. The main requirement is that when they are paired, the gap should be small, otherwise the brazier will be unstable.

By cutting a short piece into four equal parts, couplings are obtained, which are welded to the cylinder at the installation sites of the supports. After that, the brazier is installed on the legs and through drilling is performed to fix them inside the couplings. The pins inserted into these holes make it easy to carry the assembled structure - the tubes will not fall out. In addition to the sides of the portable brazier, carrying handles can be welded. By the way, during the transportation of the structure, all legs, firewood (or a package of coals) and ignition fluid can be placed inside. Such optimization will save a lot of space in the trunk.

Gallery of ready-made homemade barbecues

The side walls of the structure can be designed in the form of a funny pig

The side walls of the structure can be designed in the form of a funny pig  Steam locomotive styling

Steam locomotive styling  The support structure can be made from an old sewing machine.

The support structure can be made from an old sewing machine.  Barbecue with bottom shelf and firewood box

Barbecue with bottom shelf and firewood box  Styling the brazier under a submarine

Styling the brazier under a submarine  Shelf, located under the grill, will be very handy during cooking

Shelf, located under the grill, will be very handy during cooking  Universal building with barbecue, smokehouse and barbecue

Universal building with barbecue, smokehouse and barbecue  Additional work surfaces make the design more practical

Additional work surfaces make the design more practical  Is it still a brazier or already a steam locomotive?

Is it still a brazier or already a steam locomotive?

How to bring the design to perfection

The ease of manufacture and other advantages of a barbecue grill from a cylinder are somewhat overshadowed by the conclusions of barbecue experts that the meat in them is not as tasty as in traditional braziers. Careful examination of the problem revealed several failures.

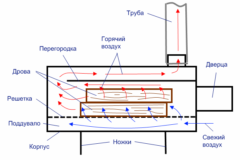

- Due to the rounded bottom, the layer of coals in the center and along the edges differs in height. This heterogeneity leads to the fact that the firewood that is on the periphery burns out much longer than in the middle of the bookmark - the heat in the center settles much faster.

- The spherical walls emit infrared rays not towards the kebab, but towards the coals, which further enhances the effect described above.

- Unlike a flat-bottomed structure, the supply of oxygen to the brazier made from a round container is uneven.

It turned out to be quite simple to eliminate the shortcoming that did not allow to get the “right” barbecue. Refinement of the brazier requires the arrangement of a longitudinal duct along the entire length of its bottom. To do this, you need a steel corner with dimensions of 80 × 80 mm and a length of 900 mm. In both of its shelves, holes with a diameter of 12–15 mm are made in increments of 50 mm. The air duct is welded into the bottom so that both of its edges remain outside. The essence of the improvement is more clear from the presented figure.

How to paint to "cheap and forever"

A metal structure must be painted for both aesthetic and practical reasons. Unprotected steel will quickly rust, which will add neither beauty nor durability to the structure. Any heat-resistant paint intended for automobile mufflers is best suited for painting the brazier, however, its high price and complex application technology do not allow us to call this option ideal. Silicone-based paints, specially designed for painting metal stoves, fireplaces, barbecues and barbecues, have the same disadvantages.

A cheap and practical material is Kuzbass varnish and similar mineral compounds based on bituminous resins.

The coating should be carried out in 3-4 layers, with a complete intermediate drying after each application. Of course, there is no need to paint the inner surface of the brazier - a soot coating, on the contrary, will contribute to obtaining an ideal product.

The disadvantages of this method are a long drying time and unpleasant, toxic fumes. In addition, the paint remains fragile for a long time, therefore it requires careful handling. The first 2-3 fires are best done "idle". This will eliminate the smell, make the coating more durable and safe. When the mineral composition is sintered, it will be very difficult to damage it. Practice shows that such a composition does not require updating for decades.

Video: how to build a brazier from a gas cylinder in three hours

Many options for barbecues built on the basis of a gas cylinder allow you to build a practical, functional and original design. It can be placed under a canopy or in a gazebo, installed in the open air or made completely mobile. A properly built brazier gives a soft and even heat, which makes the kebab soft and juicy. Therefore, all that remains to be desired is good company and bon appetit!