Without a jigsaw, many woodworking operations are impossible. Compact and lightweight, it allows you to manufacture products of even the most complex geometries. Sometimes, for example, with large amounts of work, it is more convenient to work with this tool not as a manual jigsaw, but in the format of a machine tool. Such equipment is presented in the catalogs of many manufacturers of household power tools, but if necessary, it can be made independently.

Equipment selection - main points

To begin with, it is worth answering the question: with what material will the master work most often? Motor power of 50-90 watts is sufficient for most types of wood, but if you are going to process hardwood and significant volumes, look for options in 120 watts. Stepwise adjustment of engine speed ( saw blade speed) is desirable, choose models with a smooth change in this parameter.

The ability to adjust the speed is needed to adapt the machine to work with different types of wood - heating of the material is excluded, which will spoil the cut. In addition, by gradually increasing the speed, the master concentrates on a complex procedure, and the engine also operates in a gentle mode, which increases its resource.

Some models provide for the possibility of cutting not only in a horizontal surface, but also at an angle, and a special scale will allow you to choose the most accurate position of the workpiece. Semi-professional and household machines allow you to change the tilt of the desktop up to 45 ° in one direction, professional - up to 45 ° in both directions.

Pay attention to the work surface. It should be massive enough so as not to sag under heavy workpieces, very smooth (so the part slides on the base without problems) and polished so as not to stain the workpiece.

When choosing equipment, it is important to remember the nominal number of revolutions. Many masters mistakenly believe that it should correspond to at least 1650 reciprocating movements of the file in 60 seconds - only with this indicator the cut will be perfectly even, without chips and notches. However, modern table-top machines from well-known manufacturers guarantee a perfect cutting line even at speeds of 700-1400 strokes per minute.

Do not forget about the maximum stroke of the saw blade - the thickness of the workpieces depends on this value. Additional options are also important:

- the presence of an engraver - add. shaft for particularly precise cuts and the manufacture of fine crafts;

- removal of wood dust and shavings from the work surface;

- illumination of the cutting zone.

How to navigate in models from different manufacturers?

There are many models of jigsaws on the modern market, but there are several main "players", and each of them has its own characteristics, advantages and disadvantages.

Enkor Corvette models are household-class machines and are not suitable for industrial use, but they are quite functional equipment, equipped with a rotary worktop to perform an oblique cut at the desired angle, a fixed stop with a degree scale.

Although the machines of this model are not designed for processing massive workpieces, the manufacturer offers a 150 W drive. The motor is a collector type, quite noisy and prone to overheating, unable to work without interruption and requiring regular replacement of brushes.

The amplitude of the saw stroke is 40 mm, the oscillation frequency is 700 in 60 seconds (in some modifications, a second speed is added - 1400 per minute to select the optimal mode when processing wood of different hardness). The files supplied with the equipment are not of impeccable quality, so it makes sense to immediately change them to analogues from a third-party manufacturer.

The Zubr models also belong to household machines, compact enough even for use in a city apartment. The main feature of this equipment, which can be called its disadvantage, is a noticeable vibration, which interferes with the implementation of a high-precision cut.

Zubr machines are capable of processing plywood, solid wood, plastic, thin aluminum in a horizontal plane and at an angle. They also perform drilling, grinding and polishing; for this, an additional desktop and a flexible shaft with a chuck are provided in the delivery set.

Overheating of the cutting tool is prevented by the built-in cooling system, there is an electromagnetic switch to prevent accidental switching on. Files in Zubr machines are used special, reinforced, having pins at their ends.

The working surface is fenced off from the operator by a transparent casing to protect it from dust and chips, and the cutting area is cleared of sawing products by blowing to improve visibility. Efficient waste disposal is provided. The motor used is a collector type, sufficiently resistant to overloads. Its brushes are designed for long-term operation, but their quick replacement in the equipment is still provided.

For creative carpentry workshops RSW jigsaws are designed. Among their features are the minimum backlash and the most accurate trajectory of the cutting tool. The equipment provides everything for the efficient work of the operator: fencing and illumination of the working area, the ability to remove sawn products with a conventional vacuum cleaner.

In RSW machines, the file has an unusual arrangement - with the teeth down, pin files are used, they are replaced without a key. Also among the features of the equipment is the presence of the most powerful engine in the category of similar professional machine tools.

For craft workshops, art studios and serious hobbies, JSS jigsaws from the JET brand are designed. They provide a stable cutting angle, the speed of the cutting tool is changed steplessly by the built-in electronic system.

The manufacturer offers its own branded pin-mounted files, but JSS JET equipment is also able to work with “ordinary” ones. These machines are suitable for sawing complex shapes, but the workpieces to be processed should not be unnecessarily large. Their material is wood, chipboard, plywood, fiberboard, hard and soft plastics.

The blade tension lever is located in the upper part of the machine, which increases the convenience of working with it, and the cutting blade is installed in two versions - across and along the longitudinal axis of the equipment. Dust and sawdust are easily removed by an adjustable nozzle connected to the dust extraction system. The working table can be installed at an angle, to control the accuracy of its location there is a transport scale and a stopper.

How to build a jigsaw machine on your own?

Such equipment can be made at home with your own hands, craftsmen even create such machines from old sewing machines. If you have certain skills, the drawing and design scheme are developed independently.

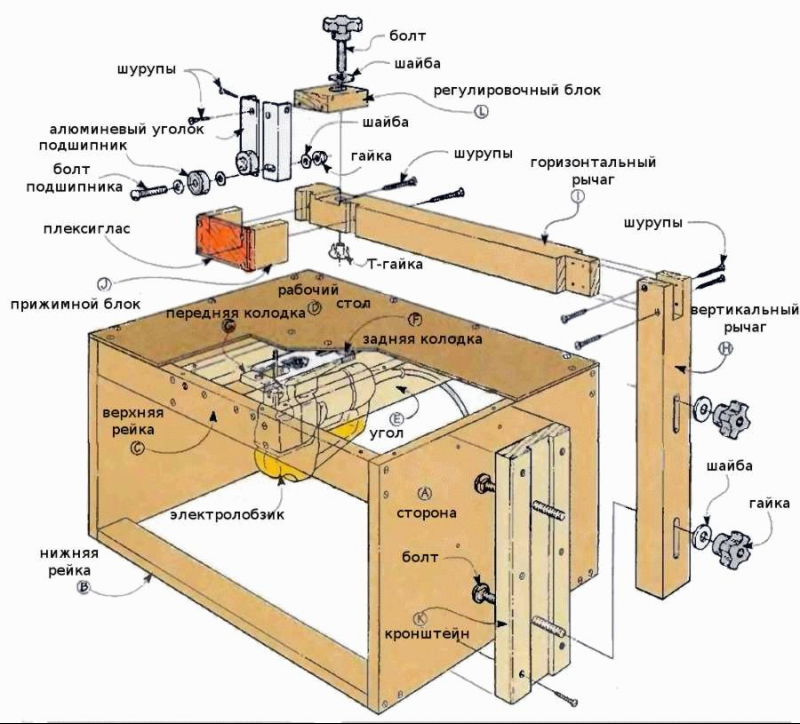

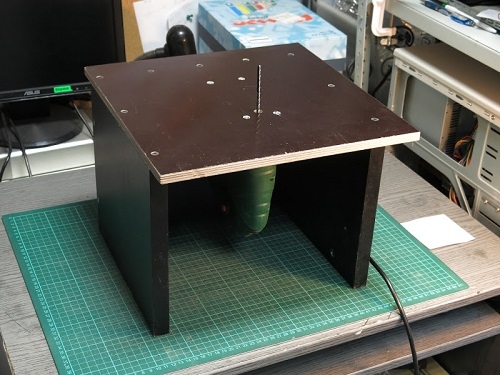

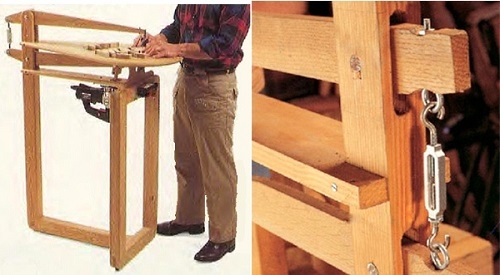

As a table, you can use a table top, a workbench, and if they are not available, a home-made structure made of laminated plywood with a minimum thickness of 10 mm. A kind of table should be built from it with a working surface size of about 500x500 mm and a leg height of about 400-500 mm. They can be two or three solid or four separate. In the first case, the design resembles a box, in the second - a traditional table on a reduced scale).

The necessary parts are cut with a hacksaw or a circular saw, and individual elements are attached to a single system with self-tapping screws. In the table lid, drill holes for fastening the tool and for the saw blade with a drill. In the sole of the jigsaw, you will also have to make mounting holes. After that, you can attach it with bolts to the tabletop so that the cutting part is brought out vertically upwards.

The advantage of such a home-made jigsaw machine is a clear fixation of the tool and a guarantee that the master's hand will lead the cut along the desired path.

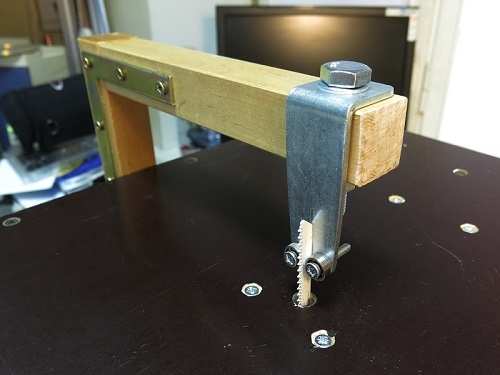

A similar version of the machine does not always form the correct curvilinear cut - the file can deviate, especially if a massive workpiece is processed. The problem is solved by rigid fixation of the cutting tool with a pair of rollers that need to be placed on an additional part.

It is made from bars with a cross section of about 50x50 mm. which are connected into an L-shaped element using a furniture corner and self-tapping screws, attached to the desktop, and at the free end a bent metal plate with rollers made of bolts and bearing parts is placed with rigid fixation.

What to do if curly and very precise cuts are needed?

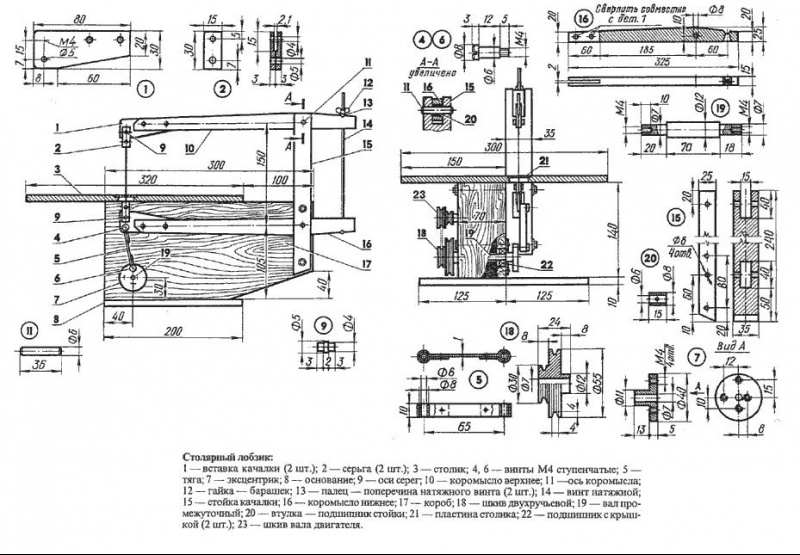

To perform the most accurate, very thin curly cuts, a home-made jigsaw machine must be equipped with a cutting blade tension system. Features of this device include:

- the fork should be used very thin - for manual jigsaws;

- the rod of the electric tool must be connected to the clamp that tensions the saw blade using a special adapter;

- as a tension block, use the clamp of a conventional manual jigsaw.

In constructive terms, the machine differs little from that described above. It is necessary to build a work table with a hole for the cutting tool and attach a clamp to the table top, and place the electric drive from below.

If cuts are needed especially precise and thin, which implies extremely delicate and slow work, it is necessary to reduce the force on the files while ensuring strong tension and precise movement. To this end, a home-made machine must be equipped with spacers on long arms instead of the traditional clamp of a manual jigsaw.

The spacer structure and shoulders holding the file are made of wood or steel. Otherwise, the design of the machine resembles a model with a manual clamp.