Manual power tool very popular both among amateurs and in the environment professionals due to their obvious merit, namely:

- comparatively cheap and availability;

- compactness;

- mobility.

Reverse side of these unconditional advantages is the presence of such shortcomings, How:

- relatively small time of continuous work;

- small achievable accuracy;

- insufficient processing quality.

Obviously, these shortcomings are devoid of professional stationary solutions - machine tools and machines on massive beds. They are, as a result, sufficient not cheap but the main thing is that they need to be placed somewhere. But what if there is no way to equip workshop, but want to improve quality works? This question is asked by many of those who are passionate about a serious hobby, and even just beginners. masters.

In our article we will talk about decision, addressing known deficiencies manual jigsaw.

Benefits of a desktop jigsaw

The general flaws hand power tools are fully inherent and jigsaw.

Its main advantage is mobility - involves only manual movements and fixation tool. That is, in fact, it turns out that:

- Very hard to do smooth, a clear cut: the slightest extra movement - and a visible flaw appears in the cut line. Going in the kit guides do not save because of their insufficient rigidity;

- Corner inclination the saw blade in relation to the workpiece is actually not controlled in any way. And even in the simplest case of a straight cut, when the blade perpendicular the sole of the jigsaw, the result may disappoint. There are at least two reasons:

- saw blade - elastic and can bend during the cutting process, the free edge of the file is not limited by anything;

- On affordable (read - cheap) models, it is quite often perfect direct the angle between the file and the sole is difficult reach by virtue of the very design of cheap stamped grounds.

Interesting Mark, what, say, American craftsmen use manual electric jigsaw is quite rare. For example, when needed cut opening in the kitchen worktop for installation sinks. In other cases, they prefer to use stationary band saws of various sizes. Such saws are completely devoid of some shortcomings (which are mentioned above), and are fully endowed with others: dimensions, weight and ... price.

Summarizing the foregoing, it is safe to conclude that, in some way fixing jigsaw on the desktop, you can to a certain extent win some of its shortcomings. And if you foresee guides free edge rollers canvases files, you can get a completely even cut. And clean - with the right choice of the file itself.

Therefore, special jigsaw table significantly improve the quality of work with this tool.

Of course, you should not think that in this way you can get full tape saw. But more on that later, now - briefly about what will be needed for manufacturing.

Materials and tools

materials can be used from those that are at hand. I would like to point out that the working surface("tabletop") must be flat and sufficiently tough, Therefore, when choosing a material, you need to keep in mind the following points:

materials can be used from those that are at hand. I would like to point out that the working surface("tabletop") must be flat and sufficiently tough, Therefore, when choosing a material, you need to keep in mind the following points:

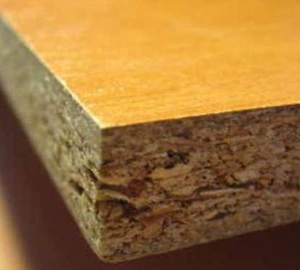

- Can be used plywood however, thin (less than 12 mm) plywood is susceptible to warping, and not the fact that the existing piece will be fairly even.

Waterproof is preferred laminated("formwork") plywood thickness from 12 mm. - If we talk about (particle boards), then in general, the thicker they are, the better - the more rigid. Ideally, a piece quality laminated kitchen countertops or "postforming".

Of the minuses - less reliability mounts to her tool, you need to take a more responsible approach to the choice of fasteners.

From pluses, perhaps the main one is accessibility and simplicity: you can order all set parts according to their size in any furniture workshop. Thickness it is better to take not the standard 16 mm, but more (for example, 22 mm). - Metal it fits almost perfectly in properties, but in everyday life it is quite difficult to find a piece of suitable size, polished and even. In addition, making the necessary holes in it is somewhat more laborious, then it is reasonable to use drilling machine.

A set of necessary tool will depend on the choices materials, but in general approximate scroll something like this:

A set of necessary tool will depend on the choices materials, but in general approximate scroll something like this:

- pencil, roulette or ruler, carpentry square - for marking;

- square will also be useful at the stage of final assembly and configuration;

- screwdrivers and nut keys according to the selected fastener;

- screwdriver or drill, drills for fasteners, self-tapping screws (screws).

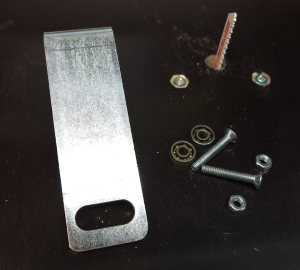

In addition, you will need rectangular metal bracket, two identical bearing and fixture. Actually myself jigsaw will also come in handy.

Manufacturing steps

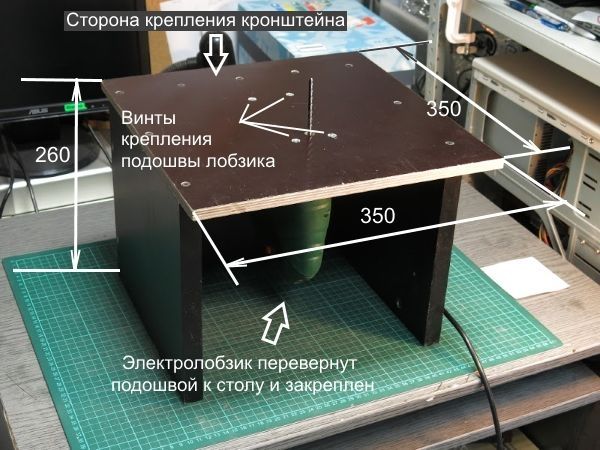

Regardless of the material chosen necessary:

- make base and connect to the work surface with holes for attaching the sole of the tool;

- make a system brackets for the top guide file;

- collect and adjust table.

Base and work surface

Dimensions grounds are chosen based on dimensions the existing jigsaw and are approximate.

The dimensions of the working surface are also indicated tentatively, from the mounting side of the bracket mounted flush with the base, on the other three sides small ledge for ease of attachment snap(clamps, stops, etc.).

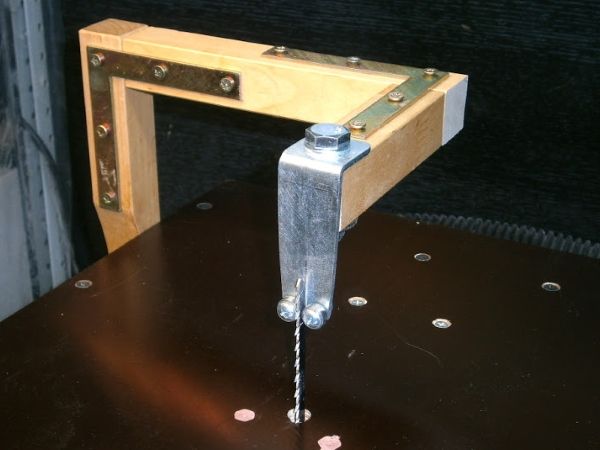

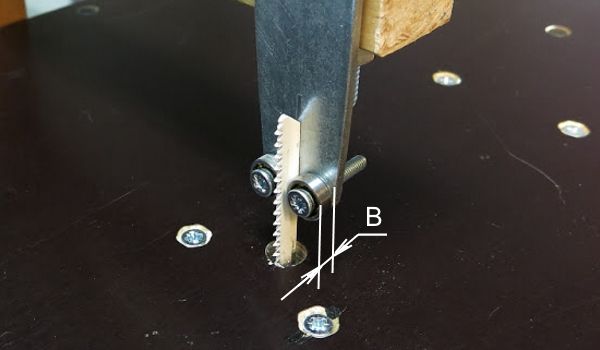

Device bracket with guide bearings is clear from the figure.

Sizes can be chosen individually, but something Necessarily must be kept in mind.

which limit the removal of the file to the side, you need pick up based on the size of the files that you plan to work with. Width the bearing itself (in the reference books it is indicated by the letter IN) must not be greater than the width files, so as not to dull her teeth.

So, for example, if width saw blades for metal (T123X, T118A) usually more than 5 mm, then they will be suitable bearings with dimension B 4–5 mm, e.g.:

Wherein prefer follows models with letters ZZ, 2RS as the most protected from exposure to dust, which will definitely be in the process of cutting.

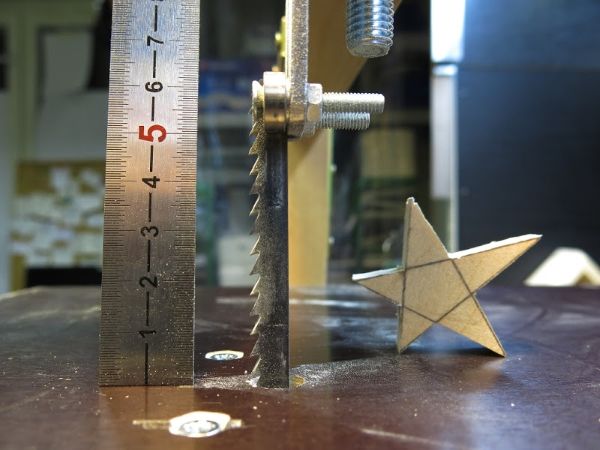

Saw blades according to tree, on the contrary, they can be narrow (T244D about 3.5 mm) and very narrow (T119BO about 3 mm, which can be used in our case). As an option - bearing 100093 (aka 693, 3 x 8 x 3 mm).

Under the selected bearing is selected fixture: screws M3 or M4, nuts (better "self-locking" with kapron insert preventing spontaneous unscrewing).

Under the selected bearing is selected fixture: screws M3 or M4, nuts (better "self-locking" with kapron insert preventing spontaneous unscrewing).

Distance between axes bearings is also calculated based on the size of the files, the thickness canvases may be within from 0.9 to 1.7 mm.

For example, thickness blade T244D is 1.25 mm, and T123X, T118A is 1 mm. Rounding is best big side.

Assembly and adjustment

bracket can to fix in the following way

This method of fastening will allow adjust and the height of the guide bearings according to the length of the saw, and (using a square) perpendicularity the saw itself relative to the desktop.

As mentioned above, you should not flatter yourself - although this is no longer easy jigsaw, but still not a band saw yet. Here are some tips:

As mentioned above, you should not flatter yourself - although this is no longer easy jigsaw, but still not a band saw yet. Here are some tips:

- In a band saw movement of the saw blade occurs only in one direction - top down, due to which the workpiece is pressed against the table by cutting forces.

It is possible to undermine the workpiece up, since the pendulum of the jigsaw makes and returnable movement.

Therefore, the workpiece needs to be well press down to the working surface of the table and the most important thing is to feed (move) the workpiece as much as possible slower.

- In a band saw movement of the saw blade occurs only in one direction - top down, due to which the workpiece is pressed against the table by cutting forces.

Note! More revs and less pitch is much better than the other way around.

- When working with a jigsaw (with or without a table), it is useful to remember that move jigsaw blades are usually of the order 15–20 mm, this value for your tool must be read in the instructions or determined by yourself. Material thicker than this value should only be sawn with divorce teeth. Otherwise shavings will not be completely removed, which is fraught with overheating and jamming of the web.

- Between the work surface of the table and sole jigsaw can pave the sheet dense rubber, having previously made an incision for the file. Assemble the table and let the canvas work a little idle so that the canvas "gets used" to the slot in the rubber. This will protect moving knots of an inverted jigsaw from a large number sawdust, for which it is not designed, because in the normal mode, the designers of the tool clearly did not count on such a number of them.

- Protective glasses - necessary. And it is also necessary to organize the inclusion of the device through pedal or provide another way instant turning off the tool. But that is a topic for another article.

- Do not be afraid creatively think and improve their tools, because any idea - just a starting point for creativity, and universal solutions do not exist.

For more information on making a table for an electric jigsaw, see video: