your mark

Nowadays, taking into account the large amount of counterfeit alcohol in stores, more and more of our compatriots are leaning towards making moonshine at home. Now there is no punishment for moonshine brewing for personal purposes, so this is a good solution for those who want to have one hundred percent high-quality alcohol at their feasts. Today, the stores offer a huge variety of a wide variety of moonshine stills, ranging from the simplest distillers to almost professional home mini-distilleries. The price also ranges from quite acceptable to very impressive amounts.

But still, for a novice moonshiner, it is better to use a home-made moonshine still. Firstly, it will be cheaper than buying ready-made equipment. Secondly, not really understanding moonshine equipment, you can ruin expensive equipment, and in the process of making a moonshine still, you will begin to understand what is needed for what and how exactly distillation occurs. Thirdly, and this applies not only to beginners, when buying a home-made moonshine still in finished form, you will not be sure of its quality or you may even run into a fake.

In this material, we will try to reveal in as much detail as possible all the subtleties of how to make a moonshine still at home. We will consider the classic version of the distiller. With it, you are unlikely to be able to make exclusive or exotic drinks like Calvados or whiskey, but it is time-tested, simple, reliable and inexpensive to assemble.

The design of the simplest moonshine still

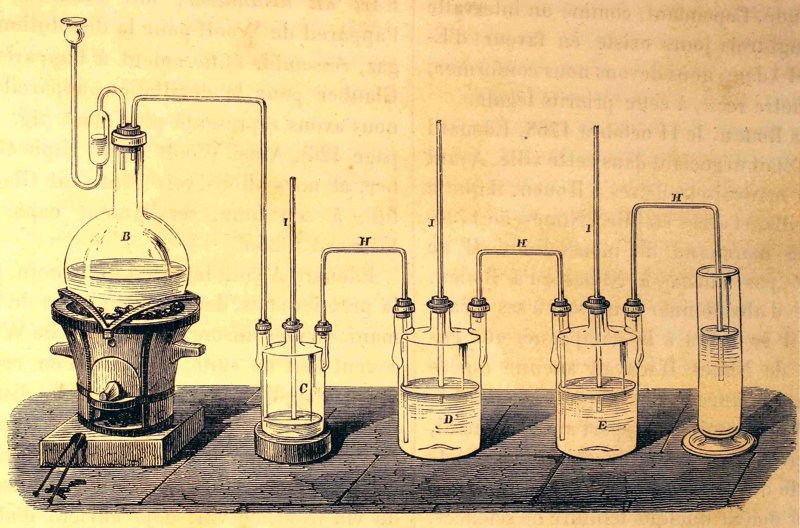

The simplest scheme of a moonshine still consists of a distillation cube and a refrigerator. Braga boils in the distillation cube, and alcohol vapors settle in the refrigerator, resulting in the formation of moonshine. However, this simple moonshine will saturate the drink with fusel oils and other harmful impurities. To get rid of them, it is necessary to add more to the design, or, as it is also called, a dephlegmator. We will tell you how to make a moonshine still from improvised means, with minimal financial investment.

alembic

So, the first element that we will consider is the alembic. A distillation cube is a container in which the mash will boil during the distillation of moonshine. What can it be made from?

Most often in old, still Soviet devices, there is a cube made of aluminum. The alembic was made from a flask or can, in which milk was previously transported. It is not recommended to use such material for the manufacture of moonshine, because aluminum partially reacts with various acids and alcohol in the mash. In addition to the fact that unnecessary impurities appear in the moonshine, with frequent use, the aluminum distillation cube begins to flow and fails after a short time.

Enamelware. Such material is neutral to acids and alcohol. If you use it carefully, do not hit or scratch it, it can last a long time even with frequent use. However, moonshine from a pot is quite difficult to seal well. Craftsmen also learned how to make cubes from a tank of a milking machine for cows, but this option is unlikely to suit a city dweller.

The most reliable option is food grade stainless steel. Such a cube will serve for a long time, it does not come into contact with mash, which eliminates additional harmful impurities in the finished product. However, cubes made of this material are quite expensive, and often ordinary galvanized steel is sold under the guise of stainless steel, and this is also not so durable.

You can also use a copper container as a cube, but as a rule, this is too expensive an option for a moonshine still.

The volume of the distillation cube must be chosen according to the volumes in which you are going to produce moonshine. Ideal for household needs from 25 to 35 liters.

One important rule to follow! Never fill the alembic completely, it should be about 80% full. This is done for safety reasons, so that when boiling, the pressure in the cube does not exceed the allowable one and the cube does not burst. When choosing a container for a distillation cube, pay attention to the width of the neck. It should be large enough to make it convenient to pour the mash and wash the cube after distillation.

Also, don't forget about the size of the container. The cube must fit on the stove, be stable and not interfere with access to the entire apparatus.

You can make an electric moonshine still. For him, the alembic is made from a pressure cooker. It has a small volume, but it has its advantages - you do not need to use a stove, as it has its own heater, and it is initially airtight. You only need to make a hole in the lid for the steam outlet pipe.

A milk can is best, preferably made of steel. This is the easiest option. Just be sure to change the rubber gasket under the lid to silicone, because alcohol vapors absorb harmful substances from rubber. This will certainly affect the quality, taste and smell of the finished product.

How to do it yourself: remove the rubber gasket, then apply silicone sealant to the edges of the cover and leave to dry. Repeat several times. Put cellophane on the neck of the can and close the lid. Keep it this way until completely dry. Get a great silicone seal.

moonshine refrigerator

The refrigerator in the moonshine still plays a very important role - it is in it that the alcohol vapor condenses and the finished product flows from there. To make a refrigerator, it is enough to understand how the principle of its operation is arranged.

The refrigerator is of two types - direct-flow and coil. A straight-through refrigerator consists of a straight metal tube that is placed in a tube with a wider diameter. Water flows continuously through this pipe, acting as a refrigerant. You can make a simple refrigerator for a moonshine with your own hands from a copper tube with a diameter of up to 10 mm and a polypropylene pipe with a diameter of more than 20 mm. Fittings with plugs are screwed onto the polypropylene pipe, holes are drilled in them with a diameter similar to that of a copper pipe. A copper tube will need to be inserted into these holes and the cracks sealed. The copper tube is connected to the distillation cube, and the fittings to the water tap.

Coils are made of glass, copper, aluminum or food grade stainless steel. Copper and aluminum have good thermal conductivity, it is easy to make a coil out of them. But they have drawbacks - they are oxidized by alcohol vapor, so they must be cleaned with vinegar or citric acid after each distillation. It is impossible to make a glass coil on your own; you can buy it in a special store. However, they are very fragile, so it is not recommended to use such devices. Food steel does not oxidize and does not release any substances into the finished product, however, the thermal conductivity of steel is three to four times lower than that of copper. The best option is considered a copper coil. In some countries, copper is even the only permitted material for the manufacture of distillers. But it must be constantly cleaned.

The longer the coil tube, the more contact with the cooling element, but tubes that are too long have poor performance. The best option is 1.5-2 meters. The inner diameter of the tube is approximately 8-12 mm.

The copper tube must be twisted in a spiral with a small distance between the turns. The coil itself is lowered into a reservoir with a coolant, usually water. Systems are closed - water is constantly in the tank and does not circulate, and open - water is constantly moving. A closed refrigerator is easier to manufacture and consumes less water, but its performance is worse - even if you regularly change the water, it heats up quickly enough, as a result of which the alcohol does not condense well. Therefore, the loss of moonshine is quite large. An open system is more difficult to manufacture, but moonshine condenses better and its quality is higher.

The easiest and cheapest option is to wind a copper tube into a spiral with an outer diameter of about 100 mm, and use a piece of 110 mm sewer pipe as a reservoir. On the sides of the pipe, drill two small holes for silicone tubes leading to the coil, place the spiral inside and close the pipe on both sides with special plugs. They also drill holes for the cold water inlet and outlet hoses. It is necessary to connect the structure to the water supply in such a way that cold water flows in the opposite direction to the movement of steam.

These elements are designed to clean steam from fusel oils and other harmful impurities. The principle of operation of the device is that the condensation temperature of these impurities is lower than the condensation temperature of alcohol, so the alcohol vapor passing through these devices is cleared of fusel oil vapor.

Sukhoparnik can be made from an ordinary glass jar with a screw cap. Two holes must be drilled in the lid for the inlet and outlet of vapors, screw the fittings into them and connect the hoses. After that, the lid is screwed onto the jar. The inlet tube must be lowered 15-30 mm lower than the outlet tube. Alcohol vapors will exit through the outlet tube, and fusel oil vapors will settle on the walls of the jar. A steamer made in this way is easy to clean and rinse.

The bubbler performs the same function as the steamer. The difference is that alcohol vapor passes through a layer of water. In the bubbler, the inlet tube descends almost to the bottom of the can, not reaching 2-3 cm. Before distillation, cold water must be poured into the bubbler. The outlet tube must not touch the water.

How to assemble a simple moonshine still

Assembling the device is very easy. A hole must be drilled to the lid of the distillation cube, to which a tube should be attached to release steam. This tube is connected to a sukhoparnik or bubbler, and from there it is connected to a refrigerator. An open cooling system refrigerator must be connected to the water supply and drain. A container for the finished product is substituted or attached under the outlet tube of the coil. The assembly of the moonshine is completed.

Pay attention to the material from which all connecting hoses are made. It is best to use food-grade silicone, it does not react with alcohol vapors in any way. The main thing is not to confuse it with PVC pipes, which begin to melt from high temperatures and harmful impurities are added to alcohol vapors. It is also impossible to use rubber, due to the fact that alcohol vapors absorb harmful substances from this material.

It is not recommended to solder the entire structure tightly after assembly. The tubes must be made easily removable, while the connection must be tight. If the tubes are made fixed, then it will be very inconvenient to maintain, wash and carry the assembled apparatus.

If desired, you can install thermometers on the distillation still or the distiller itself to make it easier to control the temperature of the process.

That's all, the homemade moonshine is ready. Now you know how to make a moonshine with your own hands. You can put the mash and start distilling, you can get your high-quality alcohol at home.

If you still have questions about the manufacture of moonshine still, then you can see photos and videos where each step is described in detail. Description and drawings of all devices can be found there.