The problem of heating is especially relevant in the private sectors and industrial parts of cities filled with warehouses and garage cooperatives. There are many ways to heat, ranging from underfloor heating to air guns and fireplaces. Most of these require long-term installation or serious financial costs, but there are those that allow you to enjoy the heat without much investment.

To create the optimal temperature regime in small and medium-sized rooms, you can make a long-burning stove with your own hands. From other devices, a home-made design is distinguished by a high level of efficiency and illegibility to combustion objects. It can function on wood, sawdust, paper, waste and other fuels. Accordingly, the cost of maintaining heat is minimal, and the return exceeds all expectations.

- After laying firewood in the firebox, user participation in the heating process is not required. Energy can be released up to 20 hours, which minimizes the time spent on refueling and servicing the furnace.

- The design does not need a solid foundation for installation, it is small in size and is characterized by low weight, as a result of which it can be installed on the ground or on a metal deck. The base must be non-combustible, otherwise a fire cannot be avoided.

- Furnaces and easily endure long-term downtime, can only be operated in severe frosts.

- A small amount of waste is generated due to the almost complete burnout of solid fuel, the remaining ash can be sprayed as fertilizer.

- Despite the fact that it is mandatory in each design, a home-made stove practically does not produce caustic gases, which is very useful in densely populated areas.

The installation of heating devices of this kind is typical for rooms up to 50-70 sq.m. In larger buildings, a water circuit is required, which is not possible in this case.

The principle of operation of a homemade wood stove

Note: A do-it-yourself long-burning furnace device is possible according to a variety of schemes, but they function in the same way.

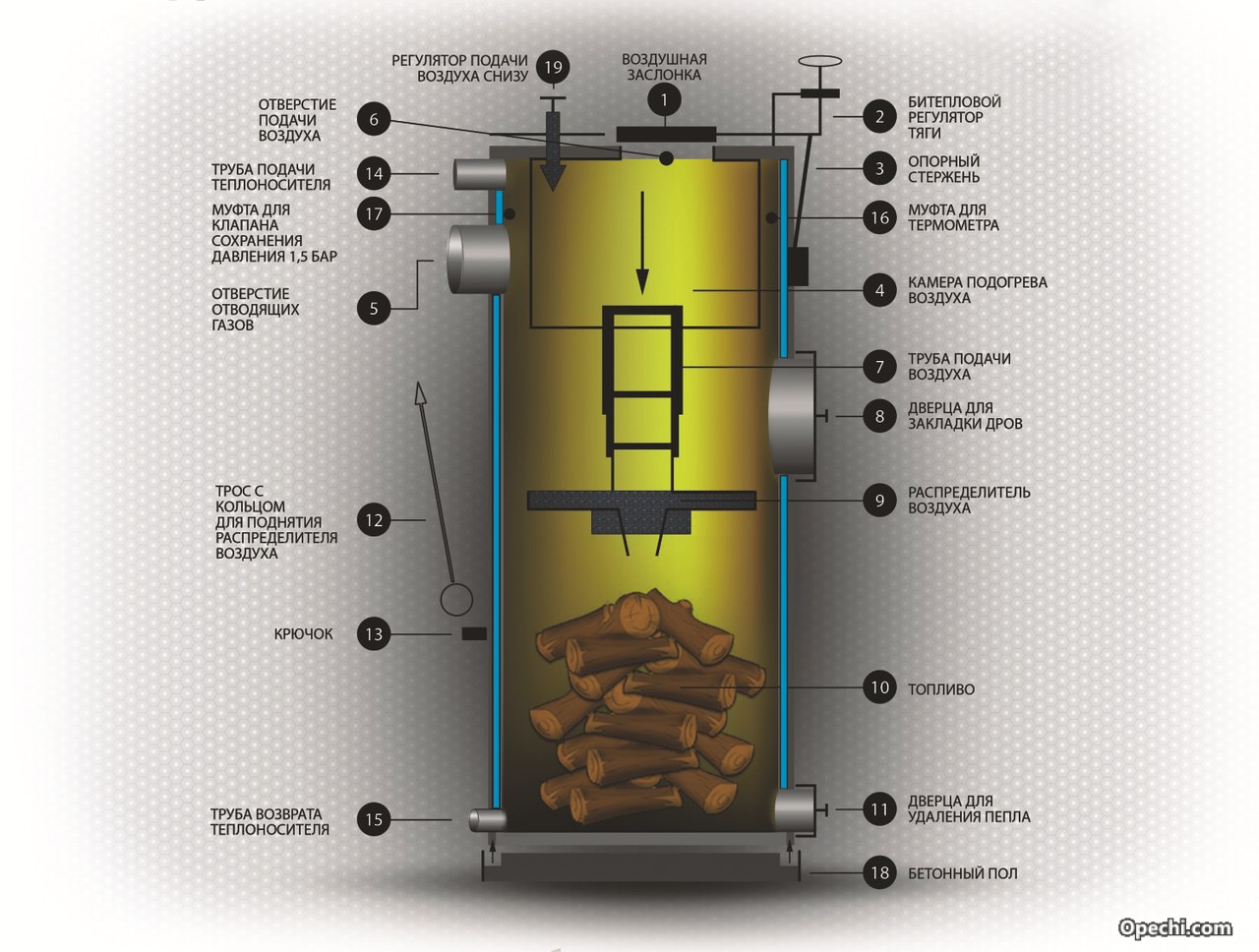

Fuel is loaded into the boiler, where it is ignited. At this time, oxygen is supplied to the furnace through special dampers. When the wood burns well, access to air is minimized, which leads to the accumulation of heavy gases such as hydrogen and methane inside the heating boiler. They give a huge release of kinetic energy. Trying to make such an increase in power in a conventional stove will lead to a lot of smoke, but will not improve the result in any way.

Preparing to create a structure

The long-burning stove consists of the main part, legs, adapters and a chimney. Like other heating elements, it must comply with all fire safety rules, otherwise sanctions may be imposed on the owner, up to and including administrative punishment. For assembly and welding, a medium-sized room is required, where it will be convenient to work with a single-phase or three-phase electrical network. If a long-burning furnace is created in an open space, then it is recommended to use generators.

Structural elements:

- a barrel, pipe, cylinder or other container with a capacity of about 200 liters, a thick sheet is also suitable;

- scrap metal or channel for assembling legs;

- steel sheets with a thickness of at least 5 mm;

- pipes with a diameter of 100-150 mm for interfacing internal departments and creating a chimney.

Home-made long-burning stoves can be assembled from improvised materials, but it is necessary to monitor the quality and tightness of the seams, as well as carefully check the fit of the dampers to avoid smoke leakage into a residential or industrial premises.

The working tools will be an angle grinder equipped with a cutting disc for metal, a welding inverter, a square and a tape measure, as well as a heavy hammer. All equipment can be found from neighbors or rented, which will significantly reduce the cost of assembling a long-burning stove with your own hands.

Note: Do not use old and rusty pipes or used raw materials - this will significantly reduce the life of a self-made long-burning stove.

You will lose a lot of time and effort, and the device will serve intermittently and malfunctions, which can ultimately lead to a fire in the room.

Structure production algorithm

- If you took the barrel as a basis, you can skip the first step. Otherwise, from the available materials, you need to create a square or cylindrical container with a bottom, but without a top. If a cylinder is used, then it is necessary to cut off the part with the valve with a grinder, if only a sheet is available, then it must be bent, a connecting seam made with autogenous and the bottom welded with a thickness of 5 mm or more.

- Legs are attached to the bottom of the future stove or fireplace for long burning. They serve for better stability and prevent the fire of the floor covering during prolonged smoldering of the fuel.

- This stage involves the manufacture of a clamping part for fuel with a channel. You will need a circle of metal, the diameter of which will be slightly smaller than the inner diameter of the barrel. It should pass freely inside the cylindrical shape. A hole with a radius of 50 mm is cut out in the center of the disc, a pipe of such length must be welded to it so that 10-15 cm protrude beyond the main heating structure. This is not a chimney, this pipe will be needed because oxygen is needed for ignition. At the top, you need to make a damper to limit the amount of penetrating air.

- To prevent smoke from entering the room, you need to make a cover. It is noteworthy that the supply pipe should also protrude from it, but there should not be large gaps between the sheet and the nozzle. 2-3 mm is enough.

- The long-burning furnace provides for a hole for cleaning spent fuel. The container must be tightly closed with a door.

- At the last stage, the chimney is welded. Its length depends on the location of the unit. The chimney cuts into the top cover of the structure. The diameter of the gas vent must be at least 150 mm.

Only one method is described here, but the general principles of assembly are clear. Often it is supposed to place a grate under the fuel - this simplifies the collection of ash. In some schemes, there are heat-conducting elements or a water circuit that will prevent a fire. Firewood can be laid from above or from the side - it all depends on the imagination and practicality of the master. A do-it-yourself long-burning stove is much different in functionality from store-bought counterparts, but it is characterized by a high level of efficiency. Of course, if it is properly designed.

How to use a homemade heater

After the long-burning furnace is completely ready, it must be tested. To do this, remove the top and pressure cover and tamp the tank with fuel. The denser the woodpile is folded, the longer the unit will smolder. Press down the fuel around the channel, close the tank tightly and light the fire. Instead of matches, you need to use a rag soaked in gasoline or kerosene, paper is also suitable. The fuel is ignited through an air pipe. Do not worry about the gas content of the room during the fire - all harmful resins are discharged through the chimney to the street. After 15-20 minutes, clog the damper; your participation in the operation of the heating system will no longer be needed for about 13-17 hours.

Technical nuances

A long-burning furnace is not at all the simplest design, like many others, it has its own characteristics in creation. Below are the main points that require increased attention from the master.

- Use natural fuel whenever possible. Cones, needles, branches, dry grass - all this contains many elements for the formation of gas, which increases the operating time of the device.

- The chimney can be split for easy cleaning, but the fewer joints, the better it will function.

- The diameter of the pipe for the chimney should not be large - this will reduce draft, and a small one will not cope with the removal of combustion products.

- The heating unit does not need to be placed close to objects and walls, installation near curtains, bookcases, gasoline tanks and so on is especially not recommended.

- Make doors for cleaning all sections of the boiler, fuel should be loaded into a clean tank - this will increase heat transfer.

A home oven is just the case where size is not the main thing. The main emphasis should be on the fidelity of the design and the quality of the fit of the seams. If the discharge of the room allows and it will not look bad from the aesthetic side - place the unit in the center of the room, so you will increase the heated area to the maximum.