After the construction of a country cottage in a place where there is no main gas pipeline, the question of heating arises. The ideal option would be to assemble a solid fuel boiler with extra-long burning with your own hands. The equipment has a number of advantages: simple maintenance, significantly lower cost for self-assembly.

The only disadvantage of heating devices operating on solid fuels is the constant control of the fuel, since after a certain period of time it is necessary to add briquettes, pellets, firewood or coal. Installing solid fuel heating boilers in a private house solves this problem, since even garbage can be used as fuel and it is enough to add fuel only a few times a day.

The principle of operation and types of solid fuel boiler

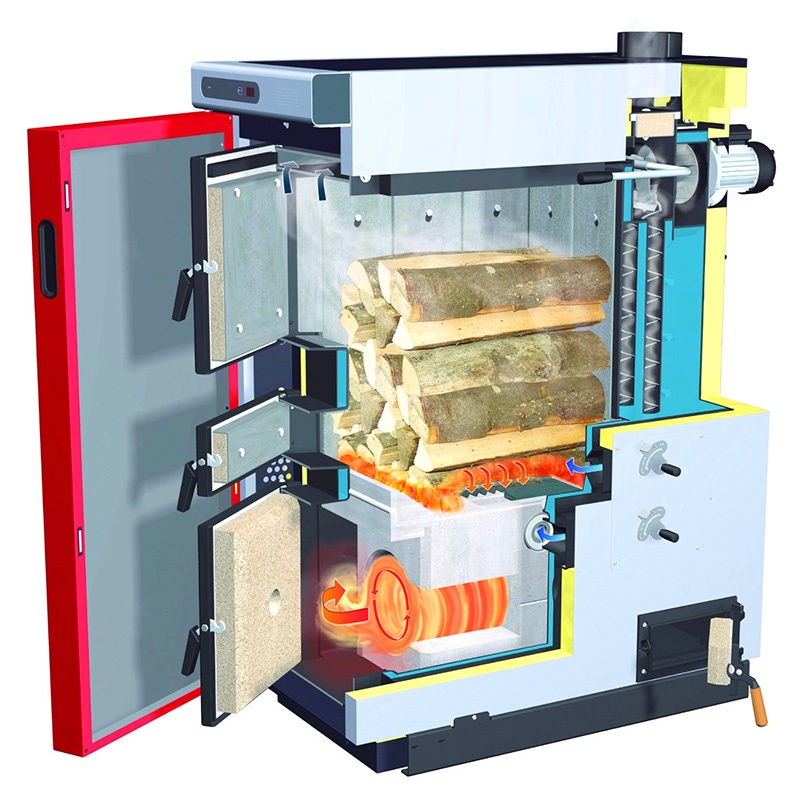

The operation of the unit is based on the smoldering of solid fuel for several hours, with minimal working out, that is, firewood or pellets burn out almost completely. Many materials can be used as fuel: old clothes and shoes, peat, garbage, firewood, and so on.

The device of a solid fuel heating boiler has a large firebox, where air is dosed into a small place where the fuel is located. The resulting gases enter the street through a pipe, the equipment is convenient to use, since fuel needs to be added 2-3 times a day.

There are several types of units that differ in the location of the combustion chamber: upper and lower.

Before considering the scheme of how to make a solid fuel boiler for long-term combustion yourself, we will analyze the arrangement of the units according to the location of the combustion zone.

In equipment with an upper combustion zone, the fuel is located below the load. During the combustion process, the load simultaneously with the zone moves down the chamber. To make do-it-yourself solid fuel long-burning boilers with an upper zone, you will need metal sheets from 3 mm thick, since exposure to high temperatures occurs along the walls throughout the entire height.

Units with a combustion zone below have the following device. Between the fuel and the walls there is free space for gas formations that occur during combustion. Smoke and gas exit through a hole in the wall. The impact of high temperatures during the operation of the equipment occurs at certain places, it is recommended to choose a thicker metal for the manufacture of the boiler.

Before starting the assembly, it is required to study in detail the device and the principle of operation of the unit, only in this case, with self-arrangement, it is possible to obtain effective equipment with a long service life for space heating.

Tip: For the arrangement of heating equipment, experts advise using trusted suppliers of steel pipes and sheets, since the durability of the equipment as a whole and the safety of operation depend on the quality of the material.

The main elements of the boiler

To make solid fuel boilers for long burning with your own hands, you will need a pipe d - 30 cm, h - 3 mm and l - 80-100 cm. When using thinner metal, the walls will burn out over time.

The boiler of this type can be divided into three zones:

- Zone for smoldering fuel;

- For bulk fuel;

- A place for the removal of gas formations, smoke and final burnout.

The air distributor of a solid fuel boiler has a hole in the middle and a metal circle. Due to which air masses enter the combustion site through a telescopic pipe. Here it is required to use metal with a thickness of 6 mm when assembling. The element must move freely - the structure must be smaller in diameter than the boiler itself. Depending on the blades and dimensions of the structure, the air masses will be regulated by the impeller. To increase the fuel burning time, the height of the distributor should be made up to 5 cm.

The distributor hole is selected up to 20 mm (with such dimensions, excess oxygen will not accumulate in the structure), and the pipe diameter is 60 mm. Productive and long-term combustion of fuel occurs due to air flows (adjustment is made by a damper).

On the top of the solid fuel boiler is a chimney for the removal of gases. The pipe is installed in a horizontal position. All models of solid fuel boiler equipment provide for a door for removing ash left after fuel combustion.

Boiler assembly technology

To assemble a solid fuel boiler for ultra-long burning with your own hands, you need to follow a certain sequence. The process will require the following building materials and tools:

- Apparatus for welding elements;

- Bulgarian;

- Metal pipe h - 3 mm and d - 300 mm, 100 mm, 60 mm;

- Metal sheets h not less than 4 mm;

Step-by-step boiler assembly algorithm

To save money, most owners are wondering how to make a long-burning solid fuel boiler themselves? To get properly functioning equipment, you need to follow the steps in the following order:

- After buying a pipe for the boiler, it is necessary to cut off a part from 80 to 100 cm long. The bottom is cut out of a metal sheet, all structural elements are connected by a welding machine. The legs are made from a channel;

- An impeller with blades less than 50 mm wide is fixed by welding to the distributor, such dimensions are necessary for maximum efficiency;

- For the most efficient combustion of fuel and air supply to the system in the required volumes, it is required to install the damper on a 60 mm pipe installed on top of the regulator;

- For the production of an air distributor, a circle is required 20 mm less than the diameter of the pipe, the element is made of a metal sheet;

- With the help of a grinder, a rectangle is cut out for the door through which the boiler will be cleaned of ash, after which a handle and hinges are attached;

- A chimney is passed through the boiler tank (heat exchanger) in a horizontal position;

- They make a cover and check the structure for tightness so that all elements are tightly closed, otherwise combustion products and smoke will enter the room.

The combustion process of a solid fuel boiler can be monitored by the smoke from the chimney. The use of heating equipment of this type is indispensable in many cases: for greenhouses, houses, premises for keeping animals and many others. Subject to the assembly process and proper maintenance, the unit is harmless to people and does not cause side effects.

Step-by-step algorithm for installing a solid fuel boiler

There are several connection schemes, but the installation algorithm for all boilers is the same:

- First, a room for heating equipment is selected, ventilation and a chimney are arranged, and the floor is prepared. For more information about what sandwich pipes and sandwich bends for building a chimney are on the market, see Termofest in Kazan will help you decide on the accessories for the chimney;

- After installing the unit, all joints with the floor (seams) are sealed with silicone sealant;

- According to the connection scheme, the return and supply pipes are fixed to the boiler;

- With the help of a transition pipe, a chimney pipe of the required section is made;

- As all elements of the system are connected, commissioning is carried out, that is, the equipment is checked for proper operation. The service life of the boiler and safety largely depends on the correct installation.

If there are no skills at all in working and connecting boiler equipment, experts recommend seeking qualified help.