For small farms - this is the best option when choosing a processing technique. The prices for new factory equipment are high, and the used option is not always available. In this case, do-it-yourself samples help out. Home-made ones with a breaking frame are very popular with farmers.

Mini-tractor fracture: what is it

Breaking frame of the tractor- these are two semi-frames, articulated by a movable hinged mechanism. This design has a number of significant advantages:

- improved balancing and, as a result, increased cross-country ability;

- small turning radius, such tractors can literally turn around themselves, which matters in small areas;

- good specific power and, accordingly, high efficiency.

Assemble the tractor do it yourself with a breaking frame is more difficult than with a solid one, but the advantages of this model justify the effort expended.

Assemble the tractor do it yourself with a breaking frame is more difficult than with a solid one, but the advantages of this model justify the effort expended. Did you know? Articulated frames are often used in the construction of all-terrain vehicles. Home-made karakats (all-terrain vehicles on low-pressure tires) with a breaking frame and all-wheel drive have gained particular popularity.

Device collection features

The assembly of such a complex device as a tractor will require significant time and financial investments.

In addition to purchasing parts and components of the unit, you need to consider that you will need some tools. If you do not have them, then you can ask your friends for help or use the rental.

What tools will be needed

Since many parts will have to be adjusted to each other, and some even made independently, then you need a lot of tools:

Required materials for construction

The device consists of multiple nodes, some can be completely taken from other equipment, some will have to be redone:

- composite frame;

- engine;

- chassis, including suspension, axles and wheels;

- assembly with brake discs;

- steering mechanism;

- seat;

- mechanism for attaching attachments.

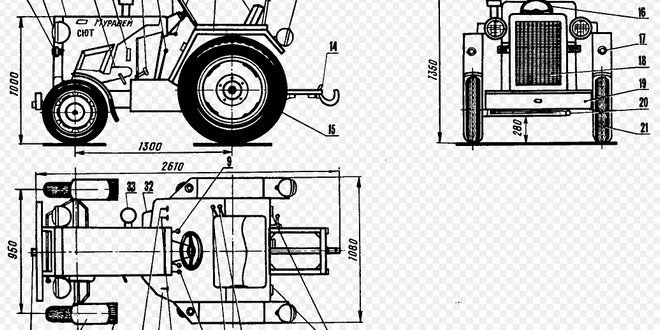

Designing a homemade tractor (drawings)

During the assembly process, you will have to articulate and adjust a lot of parts, and it is very difficult to do this without having an overall picture and detailing.  If you do not have design skills, turn to friends who can help you in such a difficult matter, or to the collective mind: on the Internet you can find a lot of options that suit you.

If you do not have design skills, turn to friends who can help you in such a difficult matter, or to the collective mind: on the Internet you can find a lot of options that suit you.

How to make a tractor with a breaking frame with your own hands

The assembly of the tractor begins with the manufacture of the frame, the phased installation of the remaining components on the base, the installation of the hydraulic system and electrical wiring. Let's take a closer look at each stage.

Frame and body

Components of the frame they are welded from metal channels (depending on the planned power of the unit, a channel from No. 5 to No. 9 is used) and they are connected to each other by a hinged mechanism (for this purpose cardan shafts from trucks are often used).  On the rear frame if necessary, mount a reinforced vertical rack for attachments.

On the rear frame if necessary, mount a reinforced vertical rack for attachments.

For the body, which does not have such loads as the frame, you can use a less expensive material. The frame, for example, can be welded from a metal rod. You will be interested to know about the technical characteristics of such tractors - tractors,. From above, the frame and the place of its articulation will then be closed with a metal sheet.

Steering and seat

Steering it is strongly recommended to equip it with a hydraulic drive: it will be very difficult to control the tractor on viscous soil in the field with one muscular force. The hydraulic system can be removed from any other agricultural machinery.  Since the suspension on the tractor is stiff, the seat should be made soft and, possibly, sprung - you will have to spend quite a lot of time in it.

Since the suspension on the tractor is stiff, the seat should be made soft and, possibly, sprung - you will have to spend quite a lot of time in it.

For home-made equipment, Ulyanovsk engines (UD-2, UD-4) are often used, but there are a lot of alternatives, ranging from the option described above with a car to engines from motorcycles, walk-behind tractors and forklifts.

Important! When using a motorcycle engine, additional forced air cooling will have to be considered - the loads of the tractor cannot be compared with its normal operation. It will also be necessary to set the gear ratio so that at a speed of about 4 km / h, the engine speed is approximately 2000 min-1. Such indicators are optimal for arable work.

wheels

Bridges (both rear and front) are taken from cars or trucks, before that shortening axle shafts to the required length. An independent suspension can be installed on the front axle (for example, from Zaporozhets), it is better to leave the rear axle rigid.  Wheels choose depending on the primary tasks of the unit. If his main work will take place in the field and on rough terrain, then it is better to put wheels with a diameter of 18-24 inches. If it will be mainly used for transport tasks, then smaller diameter wheels will do - from 13 to 16 inches.

Wheels choose depending on the primary tasks of the unit. If his main work will take place in the field and on rough terrain, then it is better to put wheels with a diameter of 18-24 inches. If it will be mainly used for transport tasks, then smaller diameter wheels will do - from 13 to 16 inches.

Additional equipment for a 4x4 tractor with a breaking frame

For productive work the mini-tractor must be equipped with a power take-off shaft (PTO) - mounted and trailed units (ploughs, mowers, harvesters) are connected to it. PTO can be taken from an old tractor or decommissioned military equipment.  If you intend to use a mini-tractor in winter, then you can equip it with a cab. Otherwise, a tarpaulin canopy is sufficient. For the convenience of working in the dark, install headlights and dimensions.

If you intend to use a mini-tractor in winter, then you can equip it with a cab. Otherwise, a tarpaulin canopy is sufficient. For the convenience of working in the dark, install headlights and dimensions.

Did you know? The first tractors appeared in the middle of the 19th century and were steam powered. Homemade mini-tractors with a 4x4 drive and a breaking frame are indispensable helpers on farm fields. You can assemble such a unit during the winter months, when there is no field work.

A cheap assembly and maintenance makes it an almost unbeatable choice for small farms.

Was this article helpful?

Not really