Owners of small workshops and just home craftsmen often have to deal with the problem of air purification after intensive work on woodworking, grinding metal surfaces, etc. Conventional ventilation of the room will not help here, you will need to install specialized equipment. With known skills, you can do it yourself.

Purpose and characteristics of cyclones

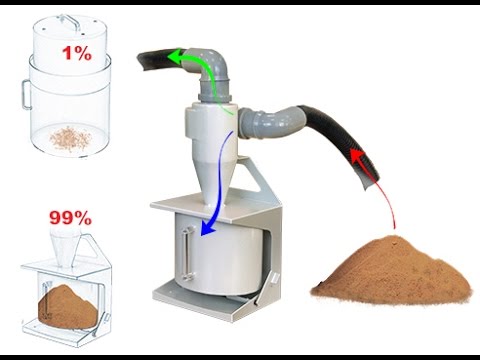

The cyclone is a specialized air cleaning unit (although similar units are also used as chip extractors, sawdust and other waste disposal agents).

As air purifiers, industrial designs of cyclones should provide suction and dust removal with an efficiency of at least 85 ... 90%, with dust removal of fragments with a size of at least 10 ... 12 microns. They are equipped with filters of various designs. The most effective are electrostatic precipitators, which simultaneously remove static electricity from dust particles.

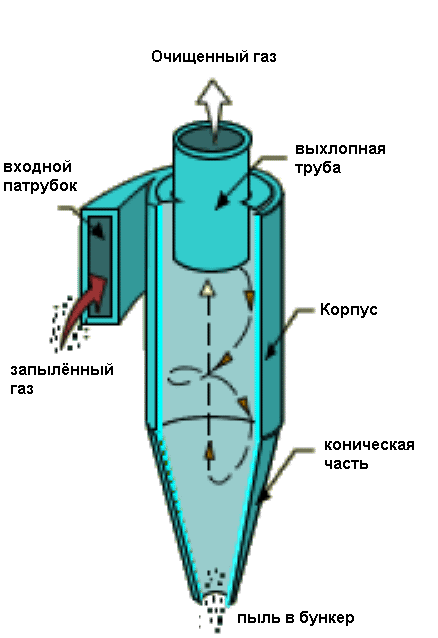

The principle of operation of the cyclone is as follows. Air enters the volute-shaped inlet space of the cyclone at a high speed (up to 20 m/s), for which fans are usually used. The air containing dust particles is swirled, after which it enters the conical cavity of the apparatus. Features of the geometric structure of the cyclone cause a gradual increase in the speed of the air flow containing dust and other waste. In the process of this, the heavier dust particles separate from the lighter ones. The former settle to the bottom, while the latter, moving in a cone-shaped space, fall into the dust collector, from where they can be easily removed using a bucket or a sealed container. Purified air is removed to the atmosphere through a pipe.

The number of cyclones, depending on the requirements for the quality of dust removal, can be made different: there are groups of three, four and even eight single cyclones.

The operational requirements for cyclones include the following parameters:

- allowable dispersion of particles that enter the cyclone, microns.

- process efficiency, which is expressed in the maximum weight concentration of particles after dust removal, in g/mm 3 ;

- cyclone performance, m 3 /h;

- boundary temperature of air or gas entering the cyclone mouth (more typical for gas cleaning systems than dust removal systems) - usually up to 400 ... 600 ° C;

- internal diameter of the cyclone, mm.

In addition to purely constructive requirements, there are also conditions for the high-quality installation of air cleaning devices. For example, when the gaps in the air duct connections are exceeded, air leakage often occurs, in which the performance of separating dust from air is sharply reduced. The allowable value of suction should not be more than 6 ... 8%.

Cyclones not only remove dust from the surrounding air, but can also provide clean indoor air.

Household cyclone design

There are no universal cyclones for various cleaning operations. For example, a chip blower should have increased pipe wall strength to prevent premature wear. With regard to a cyclone designed to collect and remove sawdust, it is important to provide for minimal losses in the suction ducts. Providing a cyclone for the purpose of air purification from cement dust that occurs in construction work, special attention is paid to the design of filters.

In domestic conditions, cyclones are considered the most versatile, purifying the air from coarse dust. By changing the design of filters, such devices can be made for dust removal purposes, as a chip extractor, for cleaning air from sawdust in a woodworking workshop (for example, at an existing sawmill).

The components of this unit are:

- body - includes a conical and cylindrical parts, and the shape of the conical part has a predominant effect on the quality of the process;

- branch pipe - one or more, where the source polluted air enters;

- exhaust pipe designed to remove dust-free air;

- inlet filter (or their system) as a chip extractor;

- receiving bucket;

- drive motor;

- fan.

All of the listed parts / assemblies can be purchased or made by hand.

Motor selection

Since a home-made cyclone is installed in the workshop, the main parameter of the engine is its power and the number of revolutions of the rotor. In the presence of a fan, the engine power does not matter much, since dust particles are still in a working machine, sawmill, etc. will not hit. However, the power and diameter of the volute of the cyclone must be interconnected. With a snail wheel diameter of up to 300 ... 350 mm, a high-speed (required!) Engine up to 1.5 kW is quite suitable. With smaller diameters, the power may be lower, but the cleaning performance will also decrease. Therefore, if there is a metalworking machine in the workshop, an engine from 1 kW is accepted.

The power of the electric motor increases significantly if you plan to equip a home-made device with your own hands outside the premises. Free space will increase, but the cleaning efficiency will decrease, mainly due to losses in the ducts. It is also worth noting that in the cold season, such a home-made cyclone will effectively “pull” heat from the workshop.

A good option should be to recognize the purchase of an electric motor complete with a receiving snail, the number of which determines the consumer capabilities of a home-made air purification system. The most common parameters of snails for domestic use and recommended electric motors for them are shown in the table:

The systems are supplied with rubber vibration isolators. They are able to create a working pressure of 0.8 kPa and above.

When choosing (or making with your own hands) a snail, preference must be given to a radial air intake pattern than a tangential one.

In the latter case, unproductive losses increase for a self-made snail, and the inertia of the particle selection method for the variant with a chip ejector will be very low.

When choosing an engine, it must be taken into account that the air velocity in the device cannot be less than 2.5 ... 3 m / s. With unsatisfactory cleaning, the elements of a home-made cyclone as a chip extractor (filter, bucket) are quickly clogged with chips, sawdust and other small waste.

Manufacturing of cyclone elements

On specialized Internet forums, you can find drawings of all the components of the unit that are available in order to make them yourself. From improvised means, an alteration of a household (or better, an industrial) vacuum cleaner is often made. Additionally required:

- a set of hoses made of translucent corrugated material (this will facilitate visual control of dust particles that have settled inside). For a chip blower, rubber hoses are more practical;

- a soundproof box that will perform two functions - it will provide a reduction in the noise level in the workshop, and additional protection of all machines and power tools located there from static electricity periodically accumulated by dust. To this end, the box can be made with your own hands from plywood, and from the inside you can finish it with any type of sound insulator;

- air ducts for purified air: they are assembled with their own hands from a thin aluminum sheet, and are interconnected by folds;

- a container for collecting waste - can be made from a conventional construction bucket with a capacity of 20 liters or more, which is sealed with a corrugated hose with the body of a home-made cyclone;

- a filter (a filter from trucks can be used), which is installed on the outlet pipe.

A vacuum cleaner remade for the needs of dust removal is checked: first at idle, driving ordinary air through the system, and then with the vacuum cleaner connected to a working machine.